ATEX expands meltblown capacity

Technology/Machinery

Tackling coronavirus with meltblown and spunbond technologies

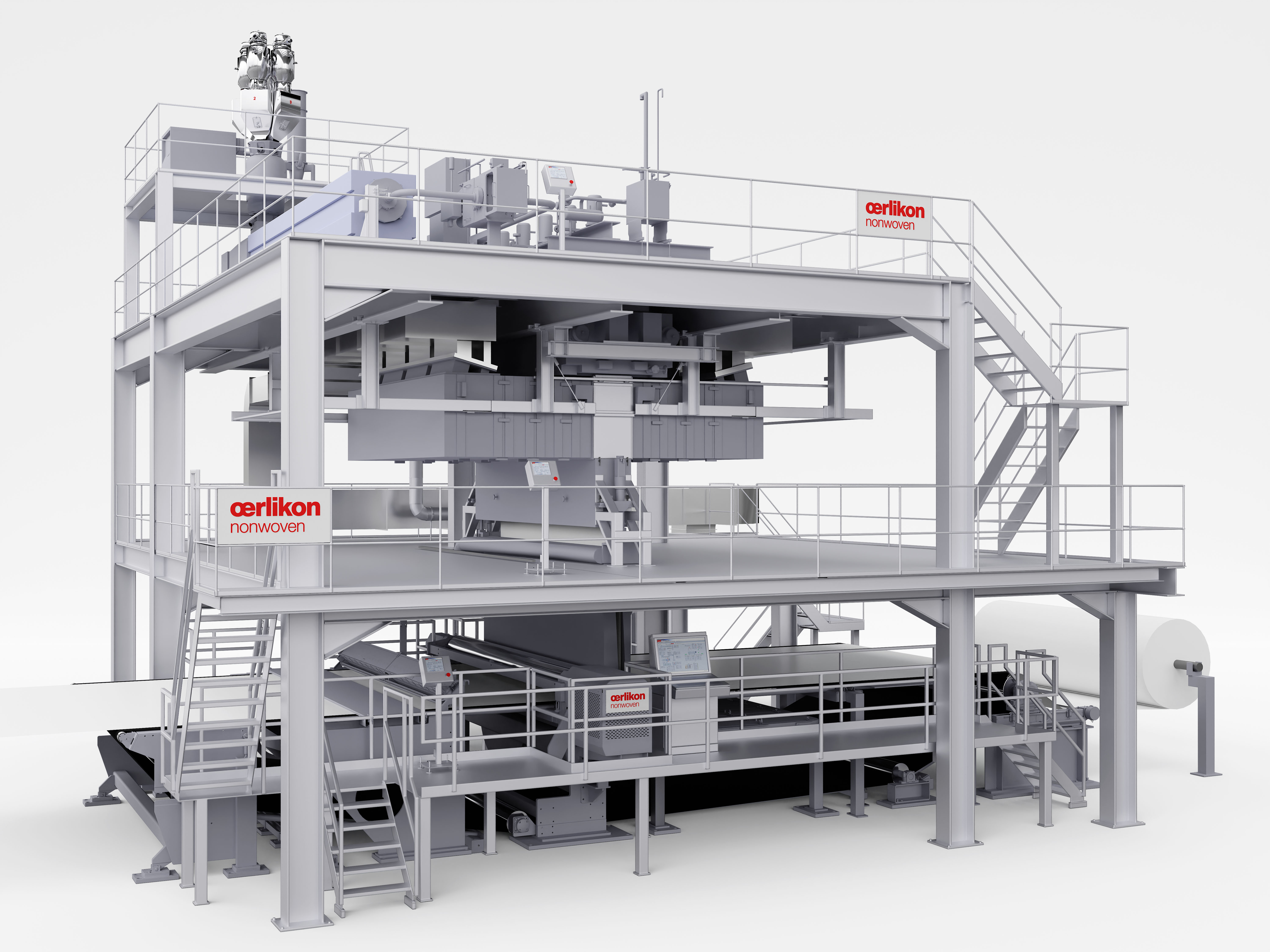

Oerlikon Nonwoven is one of only a few European systems manufacturers able to offer both meltblown and spunbond nonwovens systems.

19th November 2020

Innovation in Textiles

|

Since the outbreak of the coronavirus pandemic, the worldwide demand for protective masks and apparel has resulted in a record number of new orders worth tens of millions of Euros at Oerlikon Nonwoven. The meltblown technology from Neumünster in Germany is recognized by the market as being one of the technically most efficient methods for producing highly separating filter media made from plastic fibres, the company reports.

PPE demands high-end nonwoven products

The rising demand for protective masks and other medical protective equipment since the start of the coronavirus pandemic and the associated global ramping up of production capacities, has also resulted in an increase in the demand for nonwovens. Initially, this resulted in bottlenecks in the provision of meltblown filter nonwovens. Until then, there were very few producers of medical filter nonwovens outside of China. Meanwhile, the demand for spunbond systems has also been rising.

“Due to the structure of our group, we are in the fortunate position to swiftly reallocate and free up our production capacities. This means that we are able to relatively quickly deliver not only meltblown systems, but also spunbond equipment,” explains Dr. Ingo Mählmann, Head of Sales & Marketing at Oerlikon Nonwoven, talking about the positive situation at the company.

The capacities for respiratory masks available in Europe to date are predominantly manufactured on Oerlikon Nonwoven systems, the company says. “Our machines and systems for manufacturing manmade fibre and nonwovens solutions enjoy an outstanding reputation throughout the world. Ever more manufacturers in the most diverse countries are hoping to become independent of imports,” comments Dr. Mählmann. Oerlikon Nonwoven meltblown systems are being delivered to Germany, China, Turkey, United Kingdom, South Korea, Italy, France, North America and, for the very first time, to Australia, until well into 2021.

Quality and efficiency in demand

Depending on the purpose of the application, medical PPE should be breathable and comfortable to wear, protect medical staff against viruses, bacteria and other harmful substances and form a barrier against liquids, Oerlikon Nonwoven explains. For these reasons, they are often made of either pure spunbond or of spunbond-meltblown combinations, it says. Here, the meltblown nonwoven core assumes the barrier or filter task, while the spunbond has to retain its shape, while being tear-resistant, abrasion-proof, absorbent, particularly flame-resistant and nevertheless extremely soft on the skin, the company adds.

Oerlikon Nonwoven is one of only a few European systems manufacturers able to offer both meltblown and spunbond systems and according to the company, the systems are convincing with their combination of effectiveness and productivity, while simultaneously being highly efficient. The homogeneous nonwoven formation is said to ensure high-quality end products. “We offer our customers systems that are explicitly tailored to their requirements. We supply them with the total package – from the extrusion process all the way through to the nonwoven roll goods, all from a single source,” states Dr. Mählmann.

All masks are not created equal – thanks to the ecuTEC+

Protection against infections such as coronavirus can only be guaranteed with the right quality, Oerlikon Nonwoven says. On the one hand, this relates to how the masks are made. On the other hand, it is above all – as is so often the case – about what’s inside. Because the nonwoven used in protection classes FFP1 through FFP3 respiratory masks plays a decisive role, the company adds.

The nonwovens can be electrostatically charged in order to further improve the filter performance without additionally increasing breathing resistance. Here, Oerlikon Nonwovenʼs patented ecuTEC+ electro-charging unit excels in terms of its extreme flexibility, the company comments. Nonwovens manufacturers can freely choose between numerous variation options and set the optimal charging method and intensity for their specific applications. In this way, even the smallest particles are still attracted and reliable separated by a relatively open-pored nonwoven. Nevertheless, mask wearers are still able to easily breathe in and out due to the comparatively loose formation of the fibres. To this end, Oerlikon Nonwoven concludes, it comes as no surprise that all meltblown systems currently destined for the production of mask nonwovens are equipped with the ecuTEC+ unit.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more