Plasma nanocoating solutions on show in Mumbai

Bernd Nowack and his team of the Empa research institution, have looked at how silver coatings behave in the washing machine and assessed whether they need specific regulation.

3rd July 2014

Innovation in Textiles

|

Duebendorf

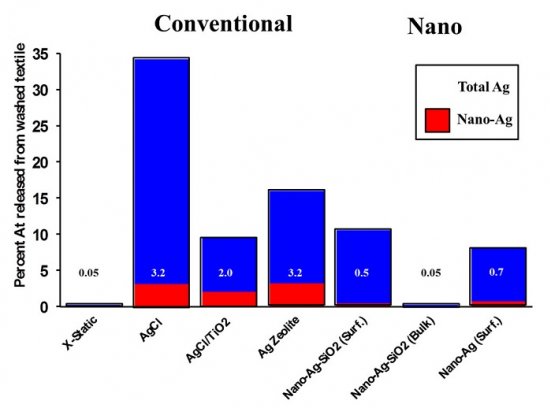

Empa, a Swiss research and services institution for material sciences and technology development, has discovered that textiles with nanocoatings release fewer nanoparticles into washing water than those with normal coatings, as a result of the institution’s investigation into how different silver coatings behave in the washing machine.

“If it contains nano, it doesn’t primarily leak nano, at least that’s true for silver coated textiles,” explained Bernd Nowack of the Technology and Society division at Empa.

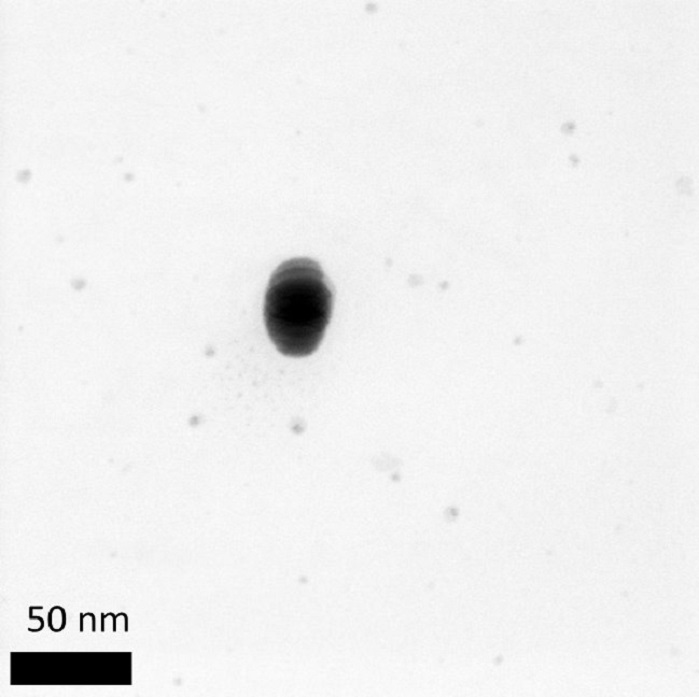

During each washing cycle a certain amount of the silver coating is washed out of the textiles and ends up in the waste water. After analysing this water, Empa found out that nanocoated textiles release hardly any nanoparticles.

That is quite the opposite to ordinary coatings, where a lot of different silver particles were found. Moreover, nanocoated silver textiles generally lose less silver during washing. This is because considerably less silver is incorporated into textile fabrics with nanocoating, and so it is released in smaller quantities for the antibacterial effect than is the case with ordinary coatings, the researchers suggest.

“All silver textiles behave in a similar manner, regardless of whether they are nanocoated or conventionally coated,” explained Nowack.

This is why, according to him, nanotextiles should not be subjected to stricter regulation than textiles with conventional silver coatings, and this is relevant for current discussions concerning possible special regulations for nanosilver.

The antibacterial properties of silver coated textiles are popular in the fields of sport and medicine. But what happens to silver particles in waste water?

Exposed silver reacts with the small quantities of sulphur in the air to form silver sulphite, and the same process takes place in the waste water treatment plant. The silver sulphite, which is insoluble, settles at the bottom of the sedimentation tank and is subsequently incinerated with the sewage sludge.

So hardly any of the silver from the waste water remains in the environment. Even if silver particles are released from the textile fabric as a result of strong sweating, they are not absorbed by healthy skin.

As a next step, Nowack's team plans to investigate how silver textiles respond to various ordinary laundry detergents. Studies have shown that some active ingredients of laundry detergents can alter the form in which silver is present.

For example, before washing, researchers have detected silver ions, i.e. dissolved silver in textile fabrics, whereas after washing they detected elemental, i.e. metallic, nanosilver or other silver compounds, such as insoluble silver chloride.

So silver textiles ultimately contain a number of silver compounds that constantly change and undergo chemical transformations. And they do not just do that during washing, according to Nowack. “Even during the manufacturing and coating processes, external influences can have an effect on the composition of the silver particles in textiles, even before the customer has got the product hanging in their wardrobe at home.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more