Granta shares details of AM Schema

Stratasys will provide visitors with the opportunity to see the Fortus 450mc Production 3D Printer running live.

22nd February 2018

Innovation in Textiles

|

Eden Prairie, MN

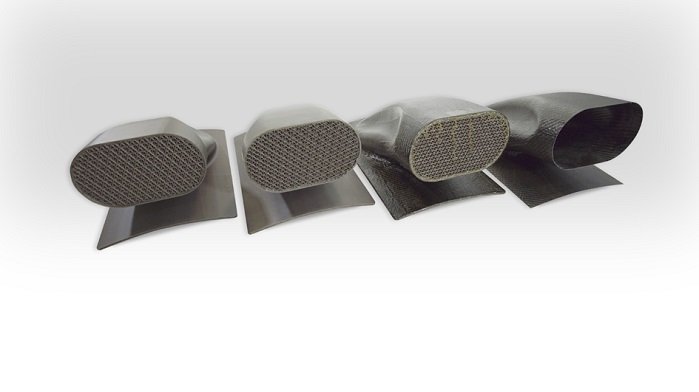

The company’s development of high-temperature materials the increased throughput of its production 3D printers, enable the manufacture of high-temperature lay-up/sacrificial tooling in hours or days, rather than the weeks or months it would take to produce and procure tooling made from traditional methods. 3D printed tooling also offers disruptive cost-savings compared to traditional tooling materials and numerous other less quantified benefits, such as dramatic weight savings.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more