Airtech introduces new LTC3 carbon prepregs

Modified epoxy can be stored at room temperature, removing time and costs by eliminating controlled temperature shipping requirements

16th August 2022

Innovation in Textiles

|

Anaheim, California

At this year’s Composites and Advanced Materials Expo (CAMX), held from October 2022 17-20 in Anaheim, California, New York-based NEXX Technologies will showcase its unique EndurEdge Max range of modified epoxy and cyanate ester prepreg materials

NEXX Technologies is streamlining the process of manufacturing prepregs – fabrics pre-impregnated with resins – with its product development in the two thermoset chemistries.

Manufacturing time is greatly decreased when compared to traditional composite prepregs in out of autoclave (OOA) and vacuum bag only (VBO) processing, with extended out time of over one year and no change in rheology and processing conditions. There are also a number of benefits for the end-user, including no freezing required – modified epoxy can be stored at room temperature, removing time and costs by eliminating controlled temperature shipping requirements – as well as no debulking or post cure requirement since the materials are optimised for the highest quality finish.

In addition, they are said to have excellent mechanical properties that meet or exceed the performance of legacy systems, emplo engineered air release channels to allow for excellent OOA/VBO processing and can be press cured in under minutes.

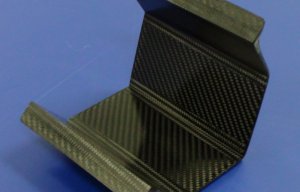

A unique impregnation process makes the prepreg materials feel like dry fabrics with relaxed fibres, to allow for easier wrapping and reduce layup time.

The prepregs are available in a variety of materials including carbon and glass fibres, Kevlar and UD tapes.

“We are showcasing the next step in prepreg composite materials and processing – from saving our customers time and money to advancing our epoxy and cyanate ester resin properties with faster and simpler processing, as well as eliminating the need for frozen storage,” said the company’s general manager Joseph Kidd. “CAMX is a great opportunity for networking and providing insight into our ongoing efforts.”

CAMX brings together suppliers, manufacturers, and engineers from a range of sectors to explore and embrace composite innovation.

To register visit www.thecamx.org.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more