FPP-based systems on display in Stuttgart

FPP unit will be primarily dedicated to the production of H2 composite tanks with dome reinforcements.

20th December 2023

Innovation in Textiles

|

Munich, Germany

Cevotec, the leading provider of automation equipment based on fibre patch placement (FPP) technology, is introducing the first FPP production system to the Japanese market.

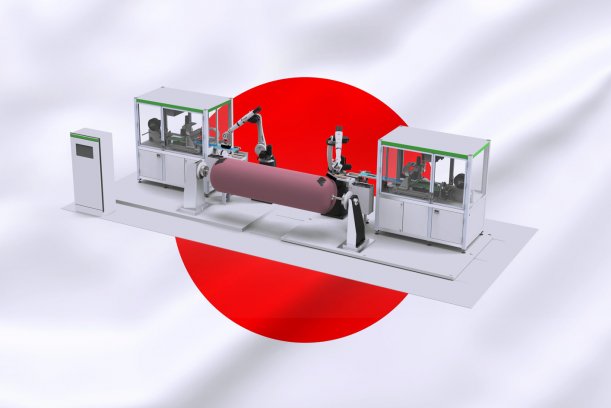

Fuji Industries, a specialised Japanese trading company in industries such as aerospace and high-tech equipment, has ordered Cevotec’s Samba Pro PV system which will be primarily dedicated to advancing H2 tank production with dome reinforcements which reduce the weight, cost and environmental footprint of composite tanks significantly

The order follows a preview of Cevotec’s new Samba Pro PV FPP system dedicated to the production of reinforcements for hydrogen pressure vessels at the 2023 JEC in Paris. Fuji is committed to advancing Japan’s composites production capabilities and support the local industry with advanced technology solutions.

“With FPP it is possible to reinforce the dome areas of type 4 hydrogen tanks which leads to significant material savings,” said Junji Yamada, president and CEO of Fuji Industries. “This technology has the potential to establish a new standard in composite tank production – it enables us to support our customers with new automation options that they need to stay competitive.”

In order to enable broad industrial and scientific engagement with the first FPP system in Japan, Fuji is planning to situate the system at a strategic R&D location accessible to relevant industry companies in aerospace and H2 and is well integrated in the Japanese composite research ecosystem.

The Samba system features a temperature-controlled automated material cutting and feeding unit and a pick and place six-axis robot for high geometrical flexibility. The robot cooperates with a length-adjustable rotational axis on which the vessel liner is mounted. Suitable liner dimensions are from 800mm to three metres in length and 300mm to a metre in diameter. The unit includes a vision system for quality inspection and position check and by placing stationary lay-up tools in free spaces of the FPP cell, the range of applications can also be extended to aerospace and automotive applications.

“We are looking forward to a successful corporation with Fuji Industries,” said Thorsten Groene, CEO and co-founder of Cevotec. “The expected fibre demand for H2 tanks will likely outgrow available fibre supply in the next 5-10 years and technologies like FPP that bring double-digit material savings will become strategically important for staying competitive long-term in the global market.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more