BMW falls for flax

Same stiffness and weight as thin-walled monolithic carbon fibre parts achieved, with the CO2 footprint down 85%.

19th July 2021

Innovation in Textiles

|

Chesterfield, United Kingdom

Composites Evolution, based in Chesterfield, UK, has teamed up with natural fibre reinforcement specialist Bcomp to launch a new range of flax-epoxy prepreg materials, designed to offer enhanced sustainability without compromising on performance.

Evopreg ampliTex prepregs combine Evopreg epoxy resin systems with Bcomp’s ampliTex flax reinforcements, to deliver a family of materials which offer outstanding performance for component applications.

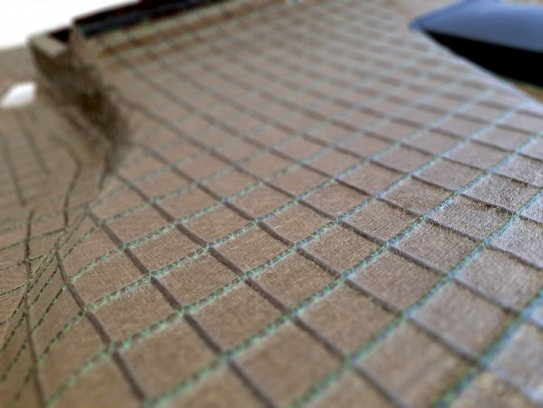

To reach the full performance of natural fibres, the new prepregs have been tailored to be compatible with Bcomp’s powerRibs reinforcement grid, enabling the same stiffness and weight as thin-walled monolithic carbon fibre parts while decreasing the CO2 footprint by 85% and improving safety thanks to a blunt braking behaviour without dangerous debris or sharp edges.

“Sustainability is an increasingly important factor for many of our customers – particularly those involved in motorsports and high-performance automotive applications,” said Composites Evolution sales and marketing director Ben Hargreaves. “As you’d expect in these sectors though, sustainability can’t come at the expense of performance – the two must go hand-in-hand. This is something that other prepreggers can struggle with, as natural fibres behave very differently to carbon or glass, for example.

“At Composites Evolution, we have over ten years’ experience in the development and production of natural fibre prepregs, and that shows in the quality of our materials.

“Working together with Bcomp, we can offer an unrivalled package of technical expertise and application know-how. We draw on this to help customers understand the strengths and weaknesses of natural fibre composites, and to show where and how they can be adopted without the need for significant changes to existing composite component production processes.”

One such customer is Retrac Group, one of the UK’s most experienced composites engineering companies across motorsports, automotive and aerospace. It recently used Evopreg ampliTex + powerRibs to produce a demonstrator bonnet panel for a racing supercar.

“We’re seeing a growing interest in flax fibre composites, particularly in the motorsports and niche vehicle sectors,” said Retrac project manager Alan Purves explains. “It is therefore essential that we have developed an in-depth understanding of the processing requirements and performance capabilities of these materials, and are ready to respond to our customers’ requirements. Being able to tap into the combined expertise and experience of both Composites Evolution and Bcomp is proving invaluable.

“Our laminators found the Evopreg ampliTex materials very easy to use, with good drape and tack to the moulds. The finished part looks great, and we shall showcase it later in the year.”

The bonnet demonstrator is a two-part moulding, with both inner and outer produced using Evopreg ampliTex EPC300-F300T 2x2 twill prepreg, backed with powerRibs. The air duct components were 3D-printed at Retrac, using its Stratasys Fortus 450MC machine. Bonded using polyurethane adhesive to minimise A-surface witnessing, the whole assembly weighs just 4 kg.

“We absolutely share the view that sustainability and performance need to go hand in hand and are very proud that already during the development phase of Evopreg ampliTex, several OEMs and parts manufacturers have fully validated the prepregs,” said Johann Wacht, motorsports manager at Bcomp, which is headquartered in Fribourg, Switzerland. “The UK market is close to our values due to its drive for high-performance and innovation, closely linked to the heritage of motorsports and supercars. It is great to see multiple projects going live in parallel to the official launch, highlighting the huge sustainable lightweighting potential of the proven package for all areas of future mobility.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more