Prepreg growth at 10.5% annually

Materials supplied to Dubai-based Aeolos Composites for the production of the new Aeolos P30 racing yacht.

15th September 2021

Innovation in Textiles

|

United Arab Emirates

UAE-based Notus Composites is expanding its high-performance epoxy range with the new NE7 low temperature curing prepreg system.

Its new formulation allows composite manufacturers to cure components at temperatures as low as 70ËšC, reducing energy consumption and enabling more cost-effective tooling options.

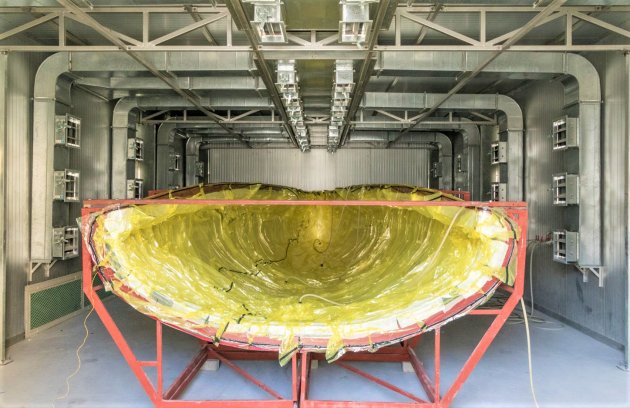

Notus Composites has developed the new NE7 prepreg system for applications across the marine, architecture, industrial and wind energy sectors, with the novel low temperature curing chemistry delivering significant cost benefits. Existing prepreg manufacturers can now use more cost-effective composite tooling, with new users able to switch easily from existing infusion or wet laminating processes without creating expensive new high temperature tooling.

The standard cure cycle for NE7 is 12 hours at 70ËšC, matching the typical cycle time for an infused part with a component Tg of 85ËšC.

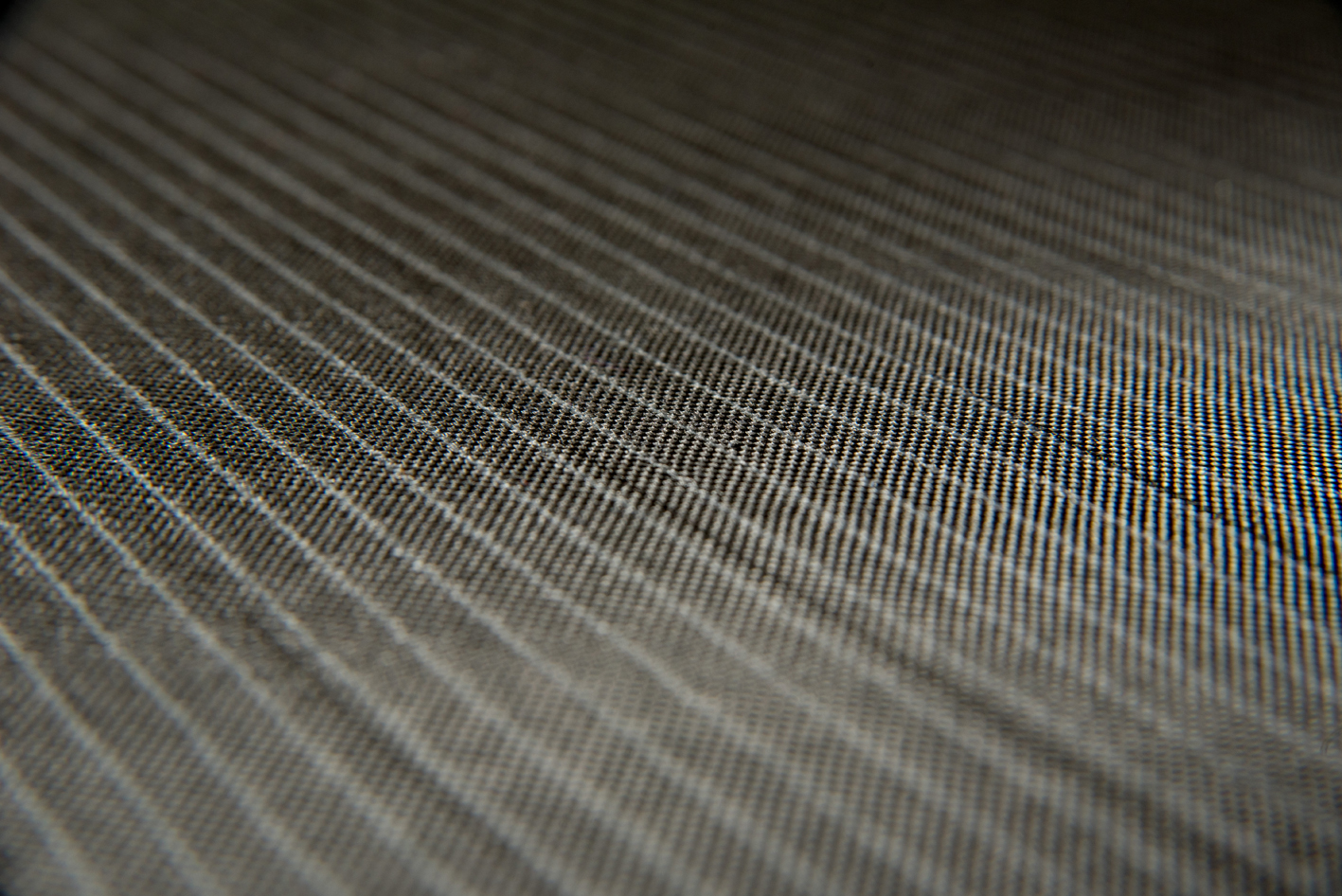

NE7 materials have a good outlife of 30 days at 20ËšC and are available in all prepreg and Notus single sided N1-Preg formats with unidirectional, multiaxial, and woven reinforcements. NE7 can also be supplied as a resin film.

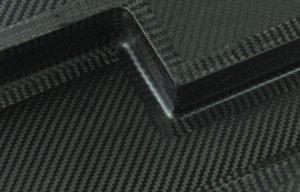

Notus has recently supplied NE7 low temperature prepregs to Dubai-based Aeolos Composites for the production of its new Aeolos P30 racing yacht. The P30 is a futuristic new craft created by top German sailor and designer, Hans Genthe, with a super light carbon fibre construction and large sail area that promises spectacular on the water performance for a thirty foot yacht. Notus delivered a range of NE7 prepregs for the build, including woven, multiaxial and unidirectional carbon fibre reinforcements, as well as adhesive films for core bonding.

“With the new NE7 prepreg system from Notus we are able to build our latest P30 design quickly, cleanly and with absolute consistency,” said Hans Genthe. “We were clear from the outset that the P30 would be a full carbon boat, and the NE7 materials provided a perfect package of mechanical performance, excellent processability, good outlife on the shop floor and low temperature curing, which made the choice of prepreg versus infusion an easy one. The P30 structure we have produced is so light and stiff it’s incredible.”

Notus Composites is also well known for the outstanding fire performance of its specialist epoxy FR prepregs. The company’s EPFR-609 FR prepreg materials (tested and certified to NFPA 285, ASTM E84 and EN13501-1) are now available with the NE7 low temperature curing technology, combining additional processing options with market leading fire performance.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more