-300x192-cropped.jpg)

NTPT and Richard Mille confirm exclusive agreement

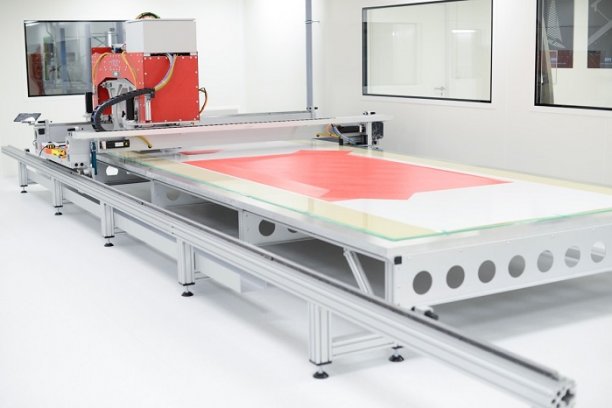

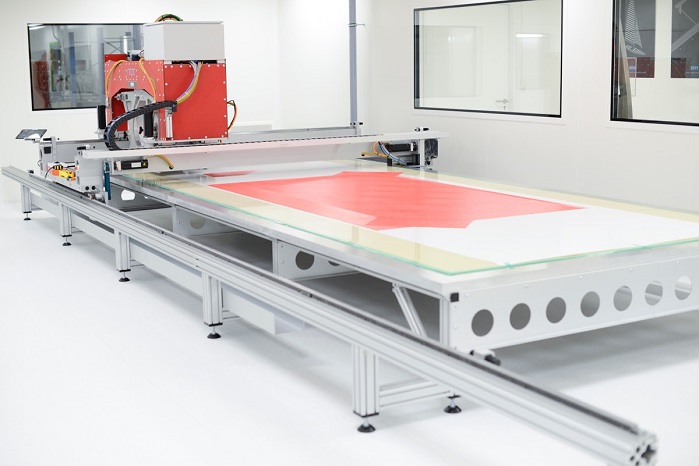

NTPT is opening new laboratory facilities and a 300 square metre cleanroom production area at its headquarters in Renens, Switzerland.

4th September 2018

Innovation in Textiles

|

Renens

NTPT, the specialist in lightweight prepreg materials and process automation technologies, is opening new laboratory facilities and a 300 square metre cleanroom production area at its headquarters in Renens, Switzerland.

This marks a further progression in the company’s long-term collaboration with GMV-Richard Mille, which includes the exclusive supply of lightweight Thin Ply materials and solutions to Richard Mille horology, jewellery and writing instrument designs. The two companies have worked together since 2013.

The cleanroom production facility will be dedicated to the manufacture of quartz and other non-carbon fibre materials. The new NTPT-designed prepreg line features amongst other things antistatic bars, a suction unit and a new creel system, to prevent contamination and to ensure optimum quality output. The new one-cubic-metre autoclave has a maximum pressure of 10 bars and maximum temperature of 260ËšC. With the capacity to produce 7,500km of fibre and more than seven tons of Thin Ply composites annually, this new line is a significant development and investment for the company.

The R&D equipment has been upgraded to increase development capacity and to facilitate improved time to market for new GMV-Richard Mille designs, and includes differential scanning calorimetry (DSC), dynamic mechanical thermal analysis (DMTA)a viscometer, microscopes and an Instron mechanical bench test.

Whilst exclusive to GMV-RM for horology, jewellery and writing instrument applications, NTPT welcomes enquiries from companies with other applications that also require a high level of contamination-free composite materials.

On site at NTPT, GMV-RM will establish a showroom of its products, where clients and others can see how these high quality, specialised composites are developed and produced.

“We are pleased to celebrate the opening of the new facilities with the team at GMV-RM,” says Ludovic Chichignoud. “This is an exciting step for NTPT and GMV-Richard Mille, which now enables us to develop advanced and highly complex composite solutions more quickly for the unique Richard Mille designs.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more