New organosheets based on cellulose

Chemically grown forests of carbon nanotubes between the can improve crack resistance by over 60%.

30th April 2024

Innovation in Textiles

|

Cambridge, MA, USA

One vulnerability of multi-layered advanced composites can be in the spaces between the fabric layers that is typically filled with bonding resins.

In the event of an impact or strike, cracks can easily spread between layers and weaken the material, even though there may be no visible damage to the layers themselves. Over time, as these hidden cracks spread between layers, the composite could suddenly crumble without warning.

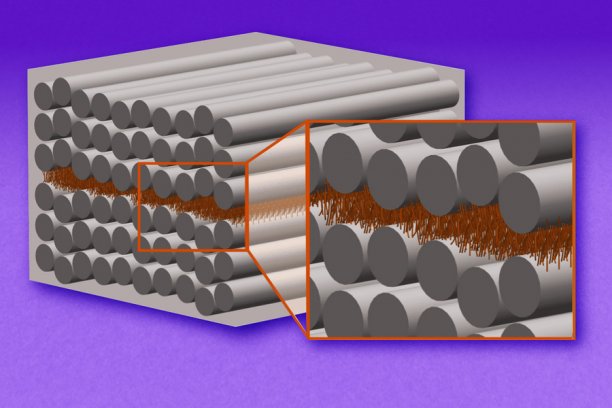

MIT engineers have now demonstrated that they can prevent cracks from spreading between a composite’s layers using an approach they call nanostitching – depositing chemically grown microscopic forests of carbon nanotubes between the composite layers. The tiny, densely packed fibres grip and hold the layers together, like ultra strong Velcro, preventing them from peeling or shearing apart.

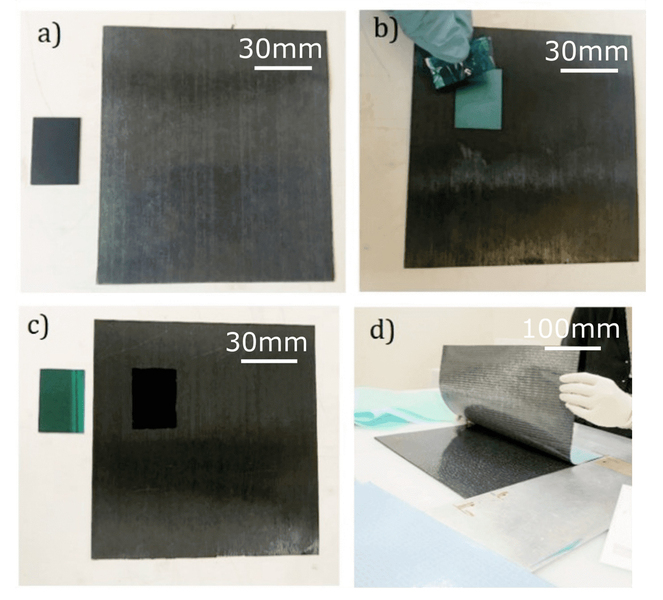

In experiments with a thin-ply carbon fibre laminate, the team demonstrated that layers bonded with nanostitching improved the material’s resistance to cracks by up to 60%.

“Composite layers can peel apart because the interlaminar region is their Achilles’ heel,” says Brian Wardle, professor of aeronautics and astronautics at MIT. “We’re showing that nanostitching makes this normally weak region so strong and tough that a crack will not grow there. We could the next generation of aircraft to have composites held together with this nano-Velcro, to make aircraft safer and have greater longevity.”

Forest growth

At MIT, Wardle is director of the necstlab where he and his group first developed the concept for nanostitching. To grow the nanotubes, the team used a process of chemical vapour deposition to react various catalysts in an oven, causing carbon to settle onto a surface as tiny, hair-like supports. The supports are eventually removed, leaving behind a densely packed forest of microscopic, vertical rolls of carbon.

The lab has previously shown that the nanotube forests can be grown and adhered to layers of composite material, and that this fibre-reinforced compound improves the material’s overall strength. The researchers had also seen some signs that the fibres can improve a composite’s resistance to cracks between layers.

In their new study, the engineers took a more in-depth look at the between-layer region in composites to test and quantify how nanostitching would improve the region’s resistance to cracks.

“Thin-ply carbon fibre laminates are an emerging composite technology, where each layer, or ply, is about 50 microns thicks, compared to standard composite plies that are 150 microns, which is about the diameter of a human hair,” Wardle said. “There’s evidence to suggest they are better than standard-thickness composites and we wanted to see whether there might be synergy between our nanostitching and this thin-ply technology, since it could lead to more resilient aircraft.”

Velcro grip

The study’s experiments were led by Carolina Furtado, who joined the effort as part of the MIT-Portugal programme in 2016, continued the project as a postdoc, and is now a professor at the University of Porto in Portugal, where her research focuses on modelling cracks and damage in advanced composites.

In her tests, Furtado used the group’s techniques of chemical vapour deposition to grow densely packed forests of vertically aligned carbon nanotubes. She also fabricated samples of thin-ply carbon fibre laminates. The resulting advanced composite was about 3 millimetres thick and comprised 60 layers, each made from stiff, horizontal fibres embedded in a polymer sheet.

Furtado transferred and adhered the nanotube forest in between the two middle layers of the composite, then cooked the material in an autoclave To test crack resistance, the researchers placed a crack on the edge of the composite, right at the start of the region between the two middle layers.

“There’s lots of ways you can get precursors to delamination, such as from impacts, like tool drop, bird strike, runway kickup in aircraft, and there could be almost no visible damage, but internally it has a delamination,” Wardle said. “Just like a human, if you’ve got a hairline fracture in a bone, it’s not good. Just because you can’t see it doesn’t mean it’s not impacting you. And damage in composites is hard to inspect.”

To examine nanostitching’s potential to prevent delamination, the team placed their samples in a setup to test three delamination modes, in which a crack could spread through the between-layer region and peel the layers apart or cause them to slide against each other, or do a combination of both. All three of these modes are the most common ways in which conventional composites can internally flake and crumble.

The tests revealed that the nanostitches held fast, and the initial crack was unable to spread further between the layers. The nanostitched samples were up to 62% tougher and more resistant to cracks, and the researchers believe that any vehicle or structure that incorporates conventional composites could be made lighter, tougher and more resilient with nanostitching.

“You could have selective reinforcement of problematic areas to reinforce holes or bolted joints, or places where delamination might happen which opens a big window of opportunity,” Furtado said.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more