New TenCate prepreg technologies at CAMX 2017

Composites

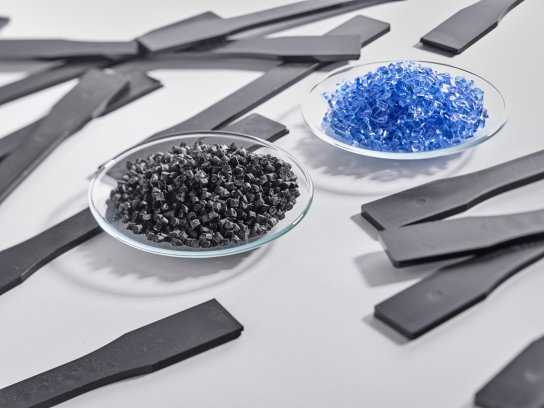

Route for recycling polycarbonate composites

The process yields new high-quality compounds.

8th June 2021

Innovation in Textiles

|

Leverkusen, Germany

Covestro and Mitsubishi Chemical Advanced Materials are cooperating with carboNXT on an industrial scale recycling process for continuous carbon fibre reinforced thermoplastics (CFRTPs).

Maezio-branded CFRTPs using polycarbonate are characterised by their light weight, high strength and flexibility in design, making waste generated during their manufacture valuable, but separating these composites has proved problematic.

“We are very excited about this joint solution, as we cannot process the materials ourselves for technical reasons,” explained Lisa Ketelsen, head of thermoplastic composites at Covestro. “By recycling according to type at our partner’s plant, the raw materials can be converted back into valuable products with similarly good properties as those of virgin materials. The recycling of materials makes it possible to use them again in other products.”

The project will now be further developed to market maturity by Covestro, Mitsubishi Chemical Advanced Materials and possibly other partners.

“Our company has many years of experience in recycling carbon fibre-reinforced thermoplastics and has the necessary plant technologies to process such waste,” added Tim Rademacker, general manager at Mitsubishi Chemical Advanced Materials. “We were therefore the partner of choice for this task. From the processed waste, we can produce high-quality new compounds of carbon fibre-reinforced polycarbonate for Covestro at CarboNXT.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more