Spunlace line number nine for Kingsafe

International technology Group Andritz has received an order from Chuzhou Jinchun Nonwoven Fabric, Anhui Province, China, to deliver a new high-speed spunlace line to its site at Chuzhou. The line will produce lightweight fabrics for the hygiene industry from 30 to 80 gsm with a capacity of up to 17,000 tons per year. Start-up is scheduled for the first quarter of 2014.

18th July 2013

Innovation in Textiles

|

Graz

International technology Group Andritz has received an order from Chuzhou Jinchun Nonwoven Fabric, Anhui Province, China, to deliver a new high-speed spunlace line to its site at Chuzhou.

The line will produce lightweight fabrics for the hygiene industry from 30 to 80 gsm with a capacity of up to 17,000 tons per year. Start-up is scheduled for the first quarter of 2014.

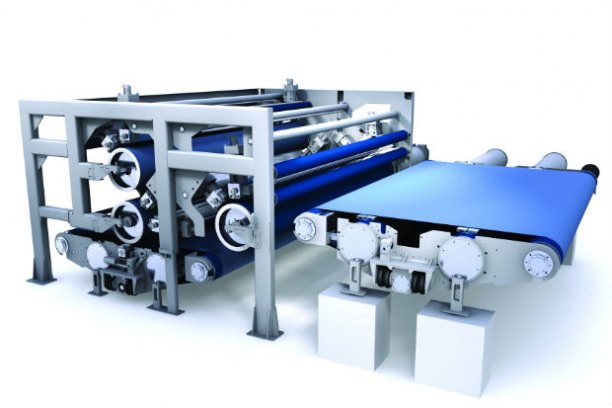

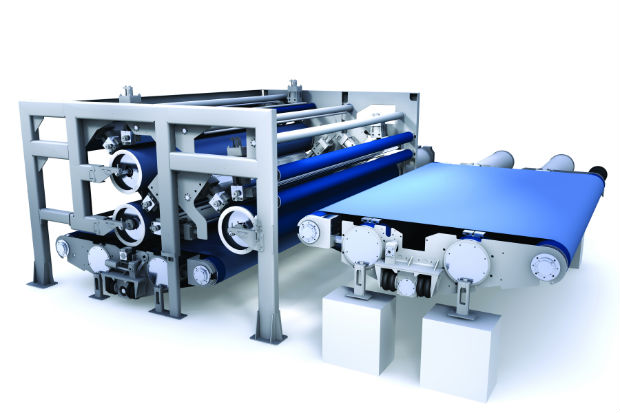

The scope of supply includes a Jetlace 3000 hydroentanglement unit, dewatering system, and a Perfodry Avantage dryer – all in-house technologies of Andritz Nonwoven. The high quality and capacity of the line as well as the expected reduction in energy consumption were decisive for the award of this order, which is said to confirm the position of Andritz as one of the leading suppliers of spunlace technology for the Chinese market.

Chuzhou Jinchun Nonwoven Fabric is one of the leading Chinese nonwovens producers. The company produces spunlace rolls for hygiene or wipes fabrics, synthetic leather or filtration applications. After start-up of this new line, Chuzhou Jinchun Nonwoven Fabric will have a total spunlace capacity of 32,000 tons per year.

Headquartered in Graz, Austria, Andritz Group is a leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors.

Andritz also offers technologies for certain other sectors including automation, the production of animal feed and biomass pellets, pumps, machinery for nonwovens and plastic films, steam boiler plants, biomass boilers and gasification plants for energy generation, flue gas cleaning plants, plants for the production of panelboards (MDF), thermal sludge utilization, and biomass torrefaction plants.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more