Techmer PM extends 3D printed tooling technology for automotive and aerospace applications

TES designed custom carbon fibre-reinforced ABS materials to help build the installation’s arc canopy printed by Branch Technology.

13th December 2016

Innovation in Textiles

|

Clinton, TN

Techmer ES (TES), a manufacturer of high-performance custom compounds used in the plastics industry, has partnered with the Department of Energy’s Oak Ridge National Laboratory (ORNL) and Branch Technology to create a large-scale installation for Design Miami utilising sustainable, bio-derived material.

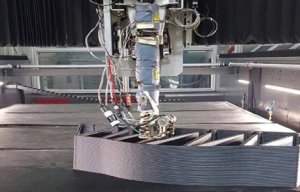

TES designed custom carbon fibre-reinforced ABS materials to help build the installation’s arc canopy printed by Branch Technology using its free-form 3D printing technology. ORNL 3D printed seating and counter space using TES’s bio-derived PLA compound that is reinforced with bamboo fibres.

The bamboo-reinforced components were printed in DOE’s Manufacturing Demonstration Facility located at ORNL using a Cincinnati Incorporated Big Area Additive Manufacturing, or BAAM, machine.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more