Technical Absorbents launches new online portal

Proprietary fibre forms magnetic bonds that are difficult to break with the water it absorbs.

3rd June 2025

Innovation in Textiles

|

Grimsby, United Kingdom

Originally founded as a joint venture between the companies Courtaulds and Allied Colloids, Technical Absorbents has now been manufacturing SAF superabsorbent fibre products for over 30 years, with its plant in Grimsby, UK, running 24/7.

Over 99% of the company’s business is exported through a network of global agents, with some tolling partners, and new applications continue to be found for SAF.

“We are not an off-the-shelf kind of business although we have a large standard portfolio,” explained Technical Absorbents commercial director Paul Rushton during a recent webinar entitled The Secret to Better Absorption. “Generally, we work collaboratively with customers to meet their specific needs and fine-tune bespoke solutions.”

Proprietary

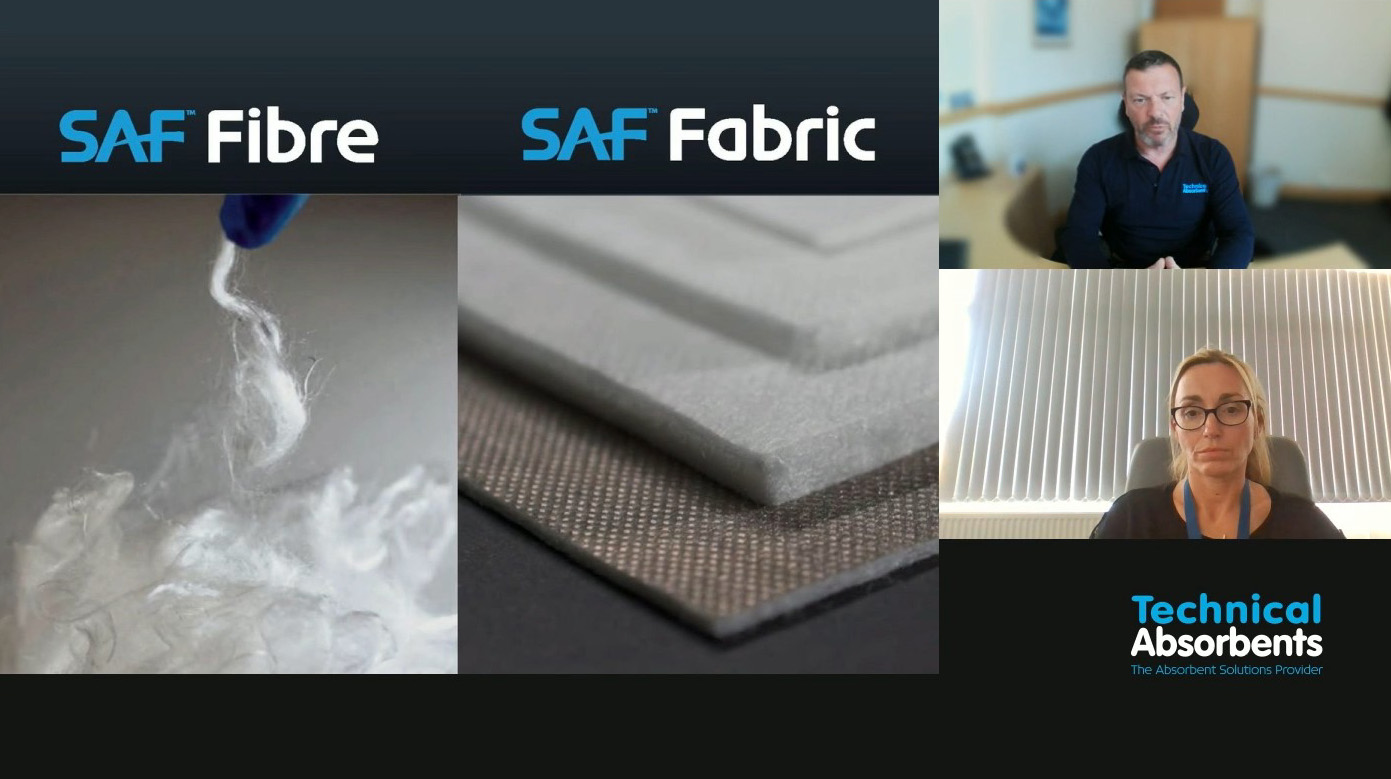

SAF fibre is based on acrylic acid and manufactured from a proprietary blend of polymers in an environmentally-friendly water based process to create an aqueous solution. This solution is then extruded in a hot air stream to dry and cure it in filament form before being crosslinked in order to control the required degree of absorbency.

SAFs performance in terms of absorbency is unrivalled, capable of absorbing 200g of water per gram of fibre, although such high absorbency is seldom called for and there is a trade off between the level of absorbency and gel integrity.

It’s also incredibly fast to absorb compared to SAP powders due to its high surface area and cylindrical shape. It forms a magnetic bond with the water it’s absorbing that is difficult to break, making it ideal for absorbent hygiene products (AHPs) such as diapers.

SAF is also truly integrated into the nonwoven with no danger of shedding, whereas constructions containing SAP in powder form usually need heat sealing. Its polyacrylate structure also makes it safe to use, and it is FDA approved for food applications.

Nonwovens

The standard range of SAF fibres for nonwovens includes a 52mm fibre engineered for the thermobonded and carded production route for products mainly employed in AHP structures.

These nonwovens are generally in the weight range of 20-80gsm and the SAF is combined with synthetics such as polyester or polypropylene, often in three-layer products with the SAF at the centre.

These very lightweight products have the ability to absorb 100 grams of water per gram of SAF and make for very cost-effective solutions in strong, thin structures.

A 6mm fibre is employed in the airlaid process in combination with wood pulp and sometimes bicomponents for bonding, for nonwovens in the weight range of 80-1,000gsm.

“We supply a significant amount of these materials to the food packaging industry for absorbent pads for meat, fish and fruit,” said Rushton. “They are soft and highly absorbent and can be further thermally bonded and laminated for additional strength.”

Needlefelt materials can be engineered with up to 80% 52mm SAF, although usually the requirement is for around 30%.

These products pick up where the thermally bonded SAF-containing nonwovens stop and are generally employed in durable and high loft products.

“We have a dedicated needlepunching line integrated at our Grimsby plant which makes some commercial products but is generally used for product development and trials,” said Technical Absorbents marketing manager Anita Bemrose.

Washable fabrics

After a number of years of intensive development, Technical Absorbents has also succeeded in developing washable SAF-containing fabrics which is now making inroads into the reusable hygiene market.

“Normally, washing a fabric is the last thing you’d want to do because in regular structures the SAF becomes gel like and the product will fall apart,” said Rushton. “Nevertheless, our R&D team has succeeded and the fabrics have been tested to withstand up to 150 washes by an independent testing house with no absorbency loss. In-house, we’ve successfully tested to 250 washes.

“Reusables are now a viable alternative to disposable AHPs and we’ve now developed them with a lot of companies.”

In addition to AHPs and food pads, other major end-use markets include wound healing, with SAF dressing meeting the need for high absorbency for exudated would healing, providing a controlled environment without wearing. The dressings can be worn for an extended period of time which cuts down then number of changes required. Filtration is another end-use area for SAF, most notably in aviation filers to remove water from aviation fuels.

Bentonite alternative

Most recently, Technical Absorbents has developed a patent-pending SAF fabric as an alternative to the bentonite-based nonwoven clay liners that are used in large-scale geosynthetic applications such as landfill containment sites.

“Our superabsorbent needlepunched nonwoven fabrics provide a thin and cost-effective extra layer of protection against below grade water entry in structural waterproofing applications,” Rushton explained. “When adhered to an HDPE waterproof membrane, the integrated SAF fibres will swell upon contact with groundwater if the membrane is breached in any way.”

This technology, he added, has been used as an effective insurance layer within power and fibre optical cables for many years but Technical Absorbents believes it could also be valuable in the geotextile industry.

In a simple in-house test, the company placed both the SAF fabric and a bentonite clay liner over an area and applied water to them. The water started to run through the bentonite fabric straight away, whereas the SAF fabric stood up to the test, absorbing and retaining the water.

A series of standard comparison tests were also run by an external test lab and the data the company received back indicates that the SAF fabrics were equal to the performance of the bentonite layers in all areas.

“Our 500gsm needlepunched fabric is ten times lighter than the bentonite fabric, which will enable huge advantages in terms of both handling and transportation, with major implications for the cost and carbon footprint of such construction projects,” Rushton concluded.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more