andPeteBanham(R)crop-300x192-cropped.jpg)

Cygnet Texkimp announces senior promotions

Reducing the risk of leaks and enhancing lifetime safety.

9th December 2025

Innovation in Textiles

|

Canada

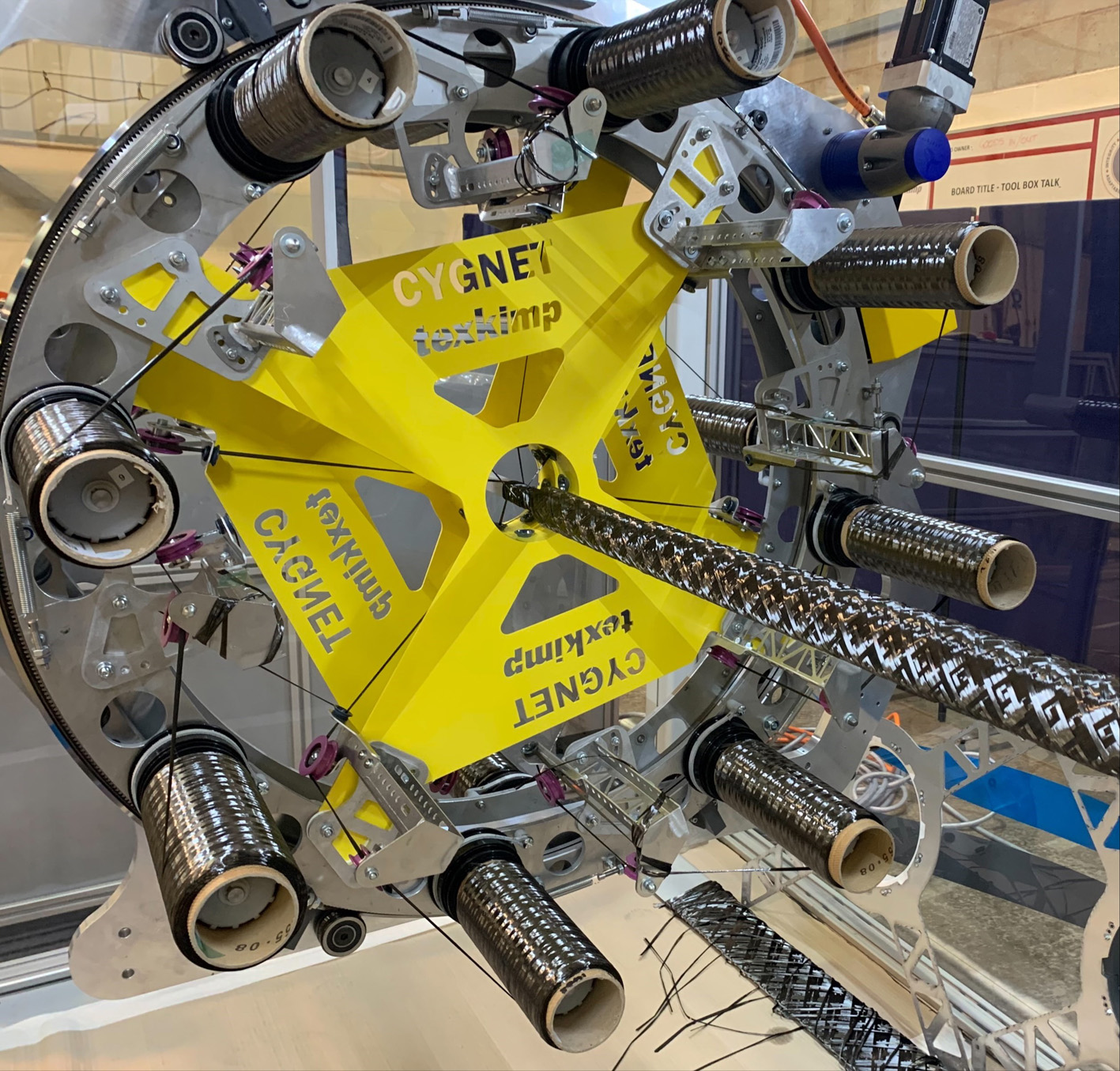

A high-speed robotic winding machine developed by UK composites technology specialist Cygnet Texkimp and the University of Manchester is being used to upgrade existing oil and gas pipelines in Canada.

Cygnet Texkimp’s multi axis winder has been commissioned by Canada-based pipeline technology company Total Containment Inc. (TCI) as part of a solution to wrap existing pipelines in carbon fibre in order to reduce the risk of leaks and enhance lifetime safety and performance.

A research-scale model of the multi axis winder was delivered to TCI’s Alberta headquarters in February 2025 to allow the company to produce and validate samples and further develop its methodology using its patented resin matrix. The company subsequently commissioned a full-scale version of the technology which is now being built at Cygnet Texkimp’s UK Innovation Centre and will be delivered to TCI in early 2026.

TCI’s solution has been developed to help oil and gas operators eliminate leaks and explosions by upgrading existing pipelines, many of which are two or three decades old. The technology helps operators meet new regulatory measures that require them to review and potentially adjust a pipeline’s design and safety in order to protect people and the environment. It also addresses the challenge of equipping pipelines to transport oil and gas under higher pressures to improve operational efficiency. The solution replaces more common practises which rely on cutting out and replacing lengths of pipe and are slower and more expensive.

“By wrapping the pipeline in our proprietary carbon fibre composite sleeve, we can contain potential leaks and ruptures and reduce the risk of explosion,” explains TCI Founder and CEO Larry Young. “In this way, we’re able to eliminate risk of ground and water contamination and its impact on ecosystems and communities, while simultaneously improving pipeline integrity, longevity and monitoring in high-risk areas. Our technology can also be installed without the need to shut down the pipeline, by first reducing pressure to a safe operating level as per regulatory requirements for pipeline integrity digs.”

Cygnet Texkimp’s multi axis winder was originally developed to wind large, continuous and curved parts, including pipes and structural beams at speed, by laying down large volumes of fibre quickly and accurately around a static mandrel. Other applications include aircraft wing spars for the aerospace industry and crash protection structures for automotive. It is a sister technology to the company’s 3D Winder which is based on the same principles but is mounted onto a robot instead of a linear track to provide greater dexterity of winding geometry. The multi axis winder has been optimised primarily for throughput, to enable manufacturers to create parts quickly and in high volumes.

Both technologies were developed as part of a collaboration between Cygnet Texkimp and the University of Manchester and are based on a prototype from the university’s School of Materials which was subsequently industrialised by Cygnet Texkimp in 2018.

TCI’s multi axis winder will be housed inside a purpose-designed modified shoring box called the TCI-Crawler. This is lowered into the pipeline trench to protect the pipeline, technology and operators, while creating the preferred environment for executing winding. The fully electric machine will feature a 54-inch split winding ring that opens to allow for it to be installed around the static pipeline and pass along it, winding as it goes. The system has also been custom designed to self-centre and self-level the winder on the pipeline during winding and is capable of accommodating variations in pipeline geometry and ground topography.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more