Custom creations for interiors

Computer science continues to evolve into all facets of the world, including changing the traditional arena of textiles manufacturing.

29th November 2017

Innovation in Textiles

|

Ithaca, NY

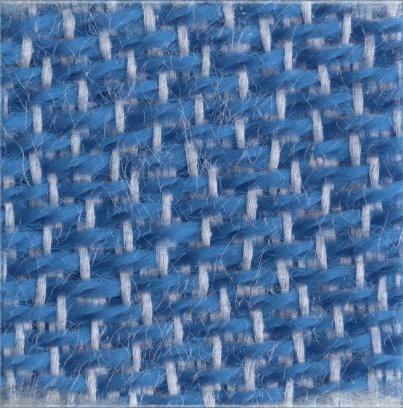

New technology developed by Cornell Professor Steve Marschner and Rhode Island School of Design Professor Brooks Hagan aims to allow woven fabrics to be automated and customised – altering the mindset that fabrics can’t be made in custom small batches.

The collaborators began with an idea to open the textile design process to anyone. “We saw an opportunity to provide a way for anyone to put any design into custom woven fabric. You can log into our web application, upload a design, and see a visual preview of the fabric while you change the weave pattern, yarn colours, etc. – and then when you like it you click print,” said Steve Marschner.

Marschner and Hagan have been working on this technology for a number of years – taking inspiration from Marschner’s research for the digital animation industry and also working with Kavita Bala, professor of computer science, and graduate student Shuang Zhao.

To get such a realistic rendering of the cloth, they scan samples in a 3D nano-CT scanner at the Imaging Facility in Cornell’s Biotechnology Resource Center, which is able to produce volume appearance models with extreme detail. “The tech is now fast and accurate enough for us to shift to a virtual product in an industry where appearance, texture and surface quality are key factors for success,” said Brooks Hagan.

The researchers founded Computational Textiles in 2015 and received a Small Business Innovation Research grant from the National Science Foundation to bring their website called Weft to market this year. Phase one of Weft is now online, enabling customisation of designs available on the site, and by late this year customers will be able to upload their own designs or photographs as well as customise the designs already available on the site.

Future design plans include being able to show the custom fabric on 3D objects like pillows or a chair. The company says it has agreements with several of the largest textile mills in the US to produce the designed-to-order fabric.

“This new technology can generate interest, creative activity, and new business opportunities for this US industrial sector. This launch is significant as it represents the first-time digital simulation tools have been applied to an ancient manufacturing platform to create easy access for designers,” said Hagan.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more