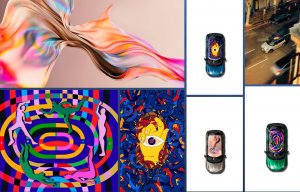

Striking rooftops for BMW MINI

Making small scale recycling possible on a local level.

20th May 2025

Innovation in Textiles

|

Paris

The Polyfloss Factory, a Paris-based social impact startup, is launching the mini Polyfloss machine as a compact, user-friendly device designed to make recycling hands-on, education, and accessible to everyone.

Inspired by candyfloss machines, the Polyfloss machine spins plastic waste into soft fibres that can be shaped into new objects – from moulded bricks to textile.

Building on years of humanitarian field experience, this mini version brings the power of circularity to workshops, design studios, textile and DIY communities, classrooms and beyond to empower them to take plastic recycling into their own hands, creatively and locally.

”We can’t rely solely on current waste management systems when it comes to plastic waste – it’s just not enough” says Emile de Visscher, CEO of the company. “We need local and creative circular economies, handled by communities and adapted to their contexts.”

“Our machine empowers anyone to take part in the fight against climate change” adds COO Audrey Gaulard. “The full-scale Polyfloss machine has already been used in humanitarian projects across Asia, Africa and the Middle East. The mini version is built on this experience, offering the same benefits in a smaller, more accessible format.

To help bring the mini machine to the world, the company is launching a Kickstarter campaign, where supporters can be the first to access the machine and join a growing community of changemakers committed to rethinking plastic.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more