Preventing ‘permastink’

Paid content

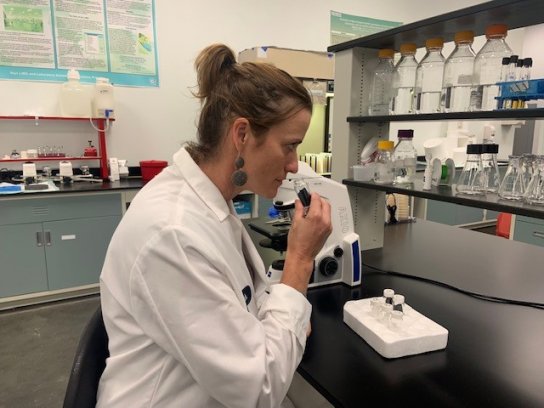

Researchers at Microban International have developed a novel strategy for evaluating the success of odour control technologies.

6th May 2022

Innovation in Textiles

|

Huntersville, NC, USA

The growth of the global sportswear market is fuelling interest in odour control technologies for textiles. Among the emerging methodologies that assess odour reduction functionality is a novel procedure that uses a synthetic formulation closely mimicking human sweat and incorporates human perception for assessment. Kate Hawley, Senior Microbiologist, and Dr Glenner Richards, Director of Microbiology and Analytical Chemistry, both from Microban International, explain their newly developed system for testing the efficacy of odour-reduction treatments in sports clothing.

Textile malodour is a major concern in the sports and athleisure wear markets. While wearing any textile article – especially during any physical exertion – body sweat is transferred to clothing. Being organic in nature, sweat is readily metabolized as a food source by skin microflora, generating chemical substances that are associated with body odour. Chemical components within sweat are hydrophobic and effortlessly bind to the synthetic fibres typically used in sports apparel, so they are not easily dislodged during washing. This adherence leads to long-term malodour retention within the fabric, causing consumers to excessively wash their clothes, so the textile articles wear out faster and end up being prematurely discarded.

Time for a change

Since sweat odours are generated by human microflora, they are best assessed using the most sensitive olfactory instrument, the nose, to detect subtle nuances in scent that lab instruments do not necessarily decipher. Therefore, trials using human subjects who are wearing articles treated with odour reduction technologies have become the most practical and accurate assessment tools for measuring the performance of these technologies in textiles.

However, this method is open to various interferences – such as personal and laundry care products, food, and environmental smells – leading to the development of in vitro studies that assess microbially induced odours on fabrics in a standard test setting. These include protocols that quantify bacterial ammonia production or the use of lactose-metabolising bacteria to coagulate milk proteins. While both procedures address the odour component of bacterial control, it is still preferable to test odour-reducing technologies using human sweat itself as the source.

Collecting sweat directly from human subjects poses several challenges, including obtaining large enough volumes for long-term investigations. Instead, many studies use synthetic sweat. However, this is limiting because only a few artificial formulations are based on the perspiration produced by the apocrine glands in the axilla (underarm) and groin regions, which are more often implicated in body odour. Therefore, these study outcomes may be less than realistic.

A fresh approach

Driven by these limitations, Kate Hawley, Dr Glenner Richards and the R&D team from Microban International have developed a novel strategy for evaluating the success of odour control technologies. They formulated an artificial sweat that simulates actual human body odour, comprising a base that uses an existing synthetic formulation, supplemented with nutrients to support microbial growth ”’ as seen on human skin in the axillary region ”’ and bacteria extracted from human sweat samples. The bacteria use natural metabolic pathways to produce human-like odourants, mimicking what would happen on our bodies. Preliminary findings show that the stench generated were far more reminiscent of human body malodour than those sourced from existing sweat formulations that do not include the supplemental nutrients.

A unique feature of this assessment method is the inclusion of a human odour panel that consists of individuals who assess odours and, therefore, the efficacy of odour reduction treatment in clothes, rather than using standard laboratory analysis. The odour panel assessors are rigorously screened and trained and are regularly retrained to objectively score and describe human body sweat odour in a consistent way.

The human component of this protocol makes testing more relevant to real world applications. After all, customers will use their own noses to detect smells in their sports clothes in real life, and they are ultimately the audience for which anti-odour textile technology is being developed. Early results show that the panel participants have been able to accurately detect clear differences between untreated textile articles and those treated with odour reduction technologies.

The sweet smell of success

This innovative approach standardises experimental conditions to remove variables and subjectivity as much as possible, improving the accuracy and reliability of assessor surveys. It provides a low cost, in vitro procedure that closely approximates real body odour on textiles and allows for comparisons between treated articles. Existing analytical techniques still have a role to play in odour-control research, and the new evaluation system supplements rather than replaces these methods. However, it is undoubtedly a valuable tool for screening during technology development, and for quality assurance during manufacturing.

The unique new methodology brings to the fore a creative solution to a long-existing problem that sportswear users are keenly aware of. A new synthetic sweat compound and a trained human odour panel could be the answer to that familiar, persistent build-up of malodour in your beloved sports clothing, another weapon for the arsenal in the fight against bad smells.

Microban International

Part of Barr Brands International (BBI), Microban International is home to the most trusted and well-known global brands in the antimicrobial, odour control, and sanitisation / disinfection markets – Microban and Ultra-Fresh. The organization has experienced over 100 collective years of growth and has revolutionised the industry. As the global leader, Microban’s proactive systems keep products cleaner, and control odours better by preventing problems before they start.

Microban International drives innovation by combining science and creative solutions that enhance high-quality consumer, textile, industrial and medical products around the world. Today, the Microban and Ultra-Fresh brands and our technologies are featured on thousands of products worldwide. The company is headquartered in North Carolina with operations in North America, Europe, and Asia Pacific.

1 Paper reference: Hawley, K., and Richards, G. 2021. Assessment of sweat odour in textiles. Microban Technology white paper.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more