Presto S for Portuguese print provider

Clients do not have time to print abroad and are moving their production to the UK, the company says.

27th August 2021

Innovation in Textiles

|

Leicester, United Kingdom

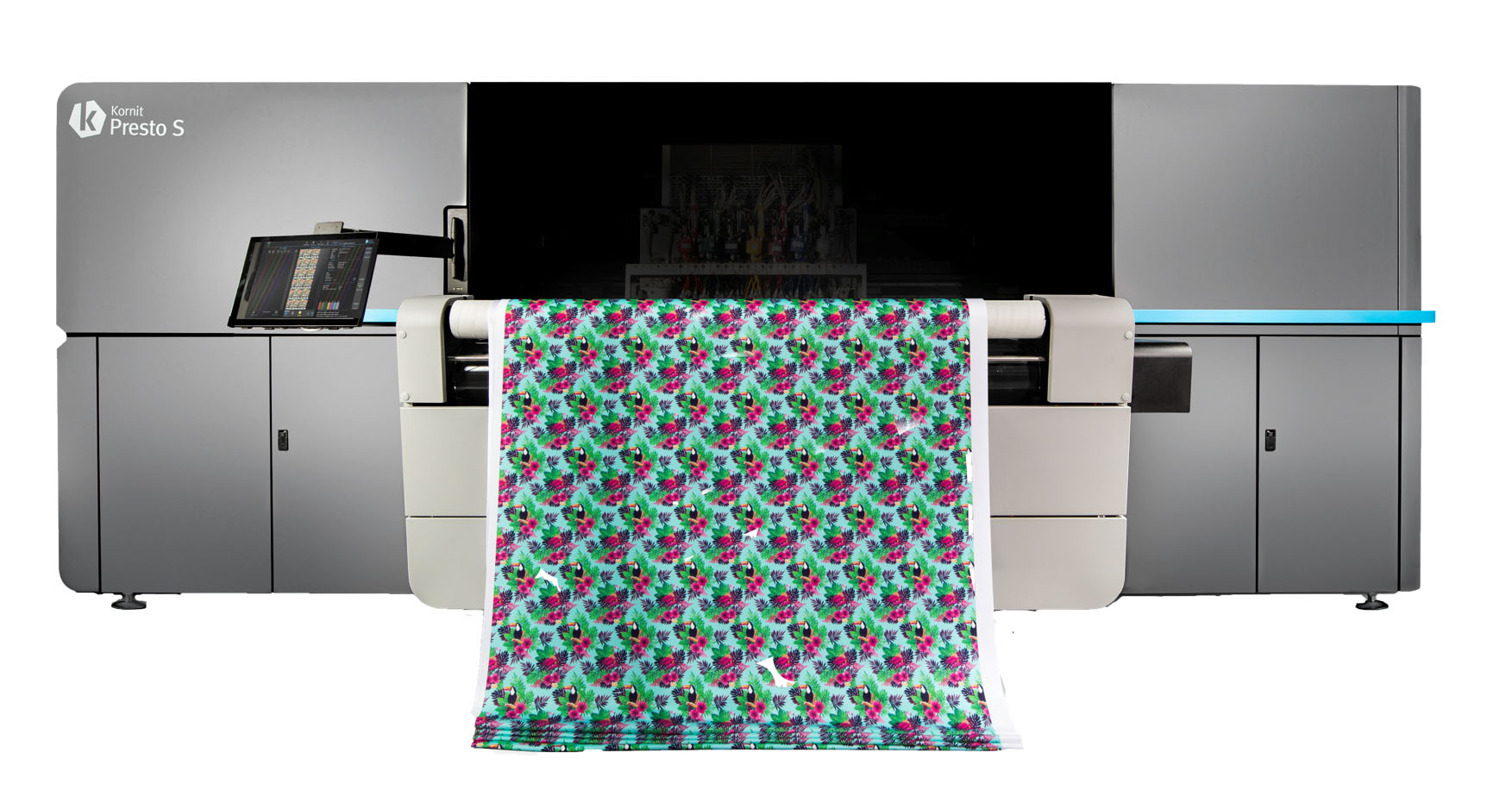

UK textile printing company Rialto Designs has invested in a new Kornit Presto S digital textile printing machine.

Founded 25 years ago by textile technologist brothers Riyaz and Mohsin Omarji in Leicester, Rialto Designs has established a loyal client base that includes many of the UK’s leading fashion brands.

In recent years, the company has downsized its analog screen production and adopted digital direct-to-garment capabilities. Two Kornit Avalanche HD6 systems for on-demand DTG production have streamlined operations and increased output to gain new market opportunities.

The latest single-step, eco-friendly Kornit Presto S helps align Rialto’s roll-to-roll workflow with commercial growth and delivers high-quality natural and synthetic pieces, in any quantity and in short orders.

Riyaz and his team recognised that the sector offered an opportunity to diversify and be ready as the fashion market shifts towards sustainable, flexible on-demand production. The company was also prepared to offer a nearshore service during the pandemic.

“The pandemic has accelerated some key market trends – reshoring in particular,” says Riyaz. “Clients do not have time to print abroad and are moving their production to the UK. They are also requiring less products and greater variation, which is combining to increase overall volumes.

“At the same time, the requirements for printed pattern diversity across multiple fibres, as well as new product groups, have also increased. We want to continue to service the fashion marketplace with millions of metres of dye sublimation prints onto polyester bases, while at the same time positioning ourselves for the inevitable market evolution. That is why we have strategically invested in our future with new technology that’s adaptive.”

Kornit’s firect to garment technology helps Rialto to deliver a service that sets it apart on speed, sustainability and quality. Clients can now order printed samples across hundreds of fabric bases – polyester and natural – and receive their orders within 24 hours.

Riyaz had been keeping a watchful eye on the pigment print marketplace, like Kornit’s proprietary pigment inks and the solution’s unique single-step process with ‘Fixation on the Fly.’

“We needed to invest in new technology to expand our services and simplify the print process,” says Riyaz. “The Kornit Presto supports inline production onto synthetics, natural fabrics and blends, creating a smoother and more streamlined production process. It has also increased speed of delivery and decreased our environmental impact.

“Buyers are becoming increasingly concerned about the environmental impact of fashion and the products they buy, so our investment in sustainable technology from Kornit has been a valuable asset during these challenging times. We are now well-placed to service our clients and expand the business.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more