Baldwin partners with Blutec

Revolutionising textile finishing by enhancing sustainability and total process control.

13th June 2019

Innovation in Textiles

|

Stockholm

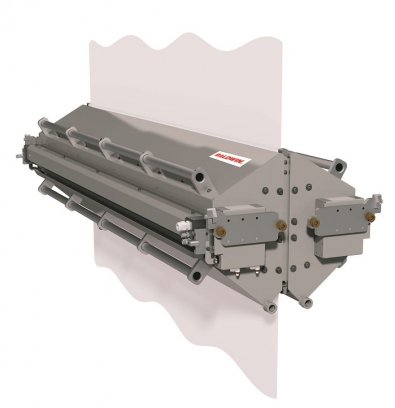

Baldwin Technology, a member of TMAS, the Swedish textile machinery association has released a new animation of the TexCoat G4 system it will showcase at next week’s ITMA 2019 trade show. It is the latest generation of the company’s non-contact precision application system for fabric finishing.

The animation can be viewed here:

The system enables a continuously high quality and productive textile finishing process with zero chemistry waste and drastically reduced water and energy consumption. TexCoat G4 will be demonstrated by Baldwin in Hall H2, stand A204 at the Barcelona show.

“We are immensely proud to launch the TexCoat G4 at ITMA 2019,” said Eric Norling, vice president of the Precision Application Segment at Baldwin Technology. “This is an opportunity to experience an innovation that drastically improves both the process and product quality, while saving time, valuable resources and contributing to a sustainable future.”

The non-contact spray technology brings numerous advantages compared to conventional methods of applying finishing chemistry. The chemistry is uniformly distributed across the textile surface and is applied only where it is required – on one or both sides of the fabric. This is highly beneficial e.g. when applying water repellants on laminated fabrics, as it eliminates the problem of chemistry affecting the quality of the adhesion layer. Furthermore, the non-contact technology eliminates chemistry dilution in wet-on-wet processes, allowing full control of maintaining consistent chemistry coverage rates. Additionally, with no bath contamination during the finishing process, there is zero downtime during colour or fabric changeovers.

TexCoat G4 will be demonstrated by Baldwin at the Barcelona show. © Baldwin Technology

The TexCoat G4 significantly improves sustainability,leading to increased profitability. 100% of the over sprayed chemistry is recycled and 0% chemistry is wasted during changeovers of chemistry, colour or fabric. As only the necessary amount of chemistry is applied to the fabric, a reduced wet pick-up level of 50% can be achieved, further leading to a 50% reduction of water and energy consumption. The low wet pick-up levels together with a single side spray application enable combined processes and can completely eliminate drying steps, e.g. for laminated fabrics and in the finishing of upholstery textiles.

“One of the biggest challenges facing the textile finishing industry is the environmental impact in terms of energy, chemical and water consumption, with continuously increasing environmental legislations and consumer demands to meet,” said Norling. “Since the TexCoat G4 reduces both water and energy consumption and has zero chemistry waste in changeovers, a significantly more sustainable finishing process is achieved.”

The TexCoat G4 can process a wide range of low-viscosity water-based chemicals. © Baldwin Technology

The TexCoat G4 offers the possibility of unprecedented tracking and control of the finishing process to secure a consistent quality. Changeovers are easily and quickly performed thanks to the recipe management including automated chemistry and coverage selection. Furthermore, the system offers automated speed tracking, fabric width compensation, real-time monitoring possibilities to track system uptime, performance, and chemistry usage, as well as active care alerts.

The TexCoat G4 can process a wide range of low-viscosity water-based chemicals, such as water-repellants, softeners, anti-microbials and more, in wet-on-wet applications and lamination processes. Additionally, the system is completely sealed, encapsulating all aerosols and thereby securing a healthy working environment for the operator.

Baldwin Jimek AB is a member of TMAS, the Swedish textile machinery association which will have a significant presence at ITMA 2019 in Barcelona.

“We’re all very excited about the introduction of the Texcoat G4 because it’s not often that an entirely new technology comes along in such a traditional field,” says TMAS Secretary General Therese Premler-Andersson. “Baldwin’s latest technology has the potential to have a huge impact on the sustainable credentials of the textile finishing industry.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more