Roth introduces high-speed winding process

Zinser and Schlafhorst will be presenting their innovative linked winding solution for ring spinning to the global public for the first time.

13th April 2018

Innovation in Textiles

|

Übach-Palenberg

Saurer’s Zinser and Schlafhorst will be presenting their innovative linked winding solution for ring spinning to the global public for the first time at the ITM trade show in Istanbul next week.

With the new Autoconer X6, Schlafhorst says it is presenting a leap in process automation to the global public at the ITM. The Bobbin Cloud material flow system with intelligent data management is designed to ensure maximum flow rates and minimum personnel requirements.

“The Autoconer X6 opens up a new dimension of efficiency with smart technology: The new, E3-certified generation offers sensationally low resource consumption, palpable productivity advantages and even more ergonomic handling. With the Bobbin Cloud material flow system based on the latest RFID technology, the Autoconer X6 guarantees maximum process reliability thanks to clever, software-controlled material management,” the company explains.

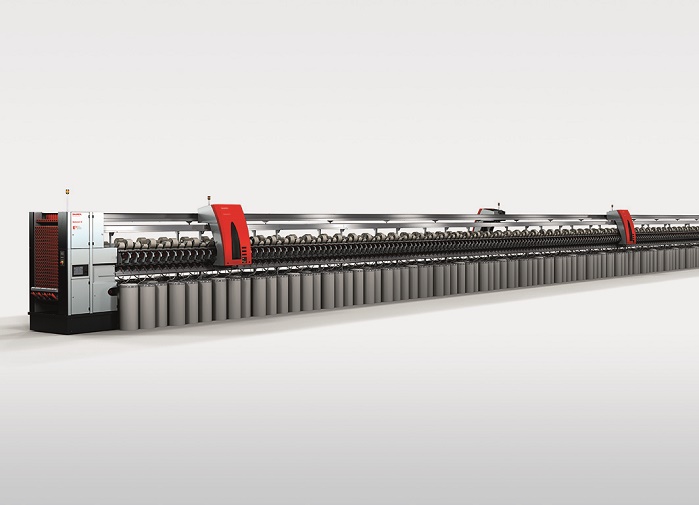

The Zinser 72XL is a ring and compact spinning machine for large spinning mills, which intend to increase their rate of return by making production particularly economical. The Zinser 72XL is said to show its advantages in almost all applications: in ring and compact yarns of any fineness, as well as in fancy and special yarns. Equipped with up to 2,016 high-speed spindles, the Zinser 72XL reduces production costs by up to 11% and the required floor space by up to 22%, according to the manufacturer.

Thanks to its single spinning position technology, achieving rotor speeds of up to 180,000 rpm and up to 720 spinning positions, the Autocoro 9 is designed to deliver highly productive technical superiority. At the same time, intelligently automated processes and lean maintenance reduce maintenance costs by up to 60% and energy consumption by up to 25%, the company reports.

The new semi-automatic BD 7 machine is also in a league of its own. It offers performance with all package sizes up to 320 mm diameter due to cross-wound packages in Autocoro quality. The BD 7 is said to reduce spinning costs and increase profitability with energy consumption savings up to 10% and rapid take-off speeds of 230 m/min for all machine lengths.

“With more than 80 years of market leadership in textile machine components in the area of spinning, today Texparts is able to offer you the basis for the production of high-quality staple fibre yarns,” the manufacturer reports. “The PK 2630 SE weighting arm series for ring spinning machines is the most versatile on the market and, together with Accotex cots and aprons as drafting system, offers the optimum solution for all yarn types in the short staple fibre range. Accotex offers a wide range of cot hardness to meet all customer needs.”

Saurer is also presenting components from Temco, Daytex and Fibervision. The brands are technology leaders in their respective sectors and offer solutions for the processing and monitoring of filament fibres and yarns.

The Saurer service station in the middle of the textiles district of KahramanmaraÅŸ offers customers service on their doorstep: 60 trained members of staff are on hand to look after all of the Turkish customers' needs. Thanks to the expanded spare parts warehouse, they can now immediately supply the spinning mills with genuine spare parts if need be.

“On the Autocoro 8 rotor spinning machine installed there, our team of experts produces sample spinnings directly on site,” the company says. Saurer has further expanded its service network with the service station in KahramanmaraÅŸ. Twenty service stations now offer customers worldwide service with fast response times and features, such as the Life Cycle Innovation Management Programme.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more