Lightening the burden of high pressure for FCEV

Driving industrial upgrading and positioning the country as a key force in textile machinery development.

29th October 2025

Innovation in Textiles

|

Singapore

The Taiwan External Trade Development Council (TAITRA), in collaboration with Taiwan Association of Machinery Industry(TAMI), held a press briefing during this week’s ITMA ASIA + CITME 2025 exhibition in Singapore to outline breakthroughs in AI-driven automation, digital process optimisation and energy-saving technologies.

The initiative underscored Taiwan’s long-standing commitment to empowering global textile manufacturers with reliable, eco-efficient solutions that balance productivity and sustainability.

Sustainable dyeing

ACME introduced the AM-ICD (intelligent conveyor drive high pressure constant speed dyeing machine), said to set a new benchmark for sustainable dyeing. Unlike traditional machines that rely on high water volumes to move fabrics, ACME’s patented mechanical conveyor system has a low liquor ratio of 1:1-1.5, cutting water, energy and chemical use by more than 65% while sharply reducing wastewater and CO2 emissions.

Its constant speed and low-tension design ensure even dye uptake with minimal shade variation and it is suitable for both circular and warp knits and nonwovens. The AM-ICD reflects ACME’s vision of transforming dyeing from a high-energy process into a smart, low-carbon operation.

Copower Technology meanwhile presented CASMAD, an intelligent system that automates the entire dye formulation process – from bottle cleaning and powder feeding to solution preparation and dispensing. With a patented anti-contamination design and RFID-based traceability, CASMAD operates 24/7 with multi-task scheduling to ensure precision and batch-to-batch consistency.

For international dyeing laboratories and production plants pursuing quality and efficiency, CASMAD acts as a central command hub, bridging R&D and mass production. It enables factories to scale smart manufacturing with accuracy, safety and full traceability, marking a key step towards total process automation.

Analytics

Kuans Micro-Auto showcased its smart dyeing analyser, a plug-and-play solution that empowers dyeing houses with real-time, data-driven insights. The system continuously monitors dye bath transparency and colour absorption rates across six light wavelengths, analysing dye compatibility, pH stability and fibre behaviour, which is particularly valuable when processing recycled materials.

By replacing trial-and-error with intelligent process control, the smart dyeing analyser helps factories shorten development cycles, reduce chemical usage and stabilise quality. Fully developed in Taiwan, it is now shaping how next-generation dyeing plants integrate AI to achieve precision and sustainability

Asia Kingdom Machinery introduced Digital Protect Technology, a digitally controlled system that automatically adjusts fabric tension and pressure during dyeing to prevent surface damage or marking. Powered by AI and servo-based torque control, the system acts as a “digital guardian”, protecting delicate performance fabrics such as spandex-rich knits and swimwear from deformation or gloss variation.

Simple to operate and easy to maintain, this innovation reduces waste and reprocessing while ensuring consistent fabric quality. With over six decades of industry experience, Asia Kingdom is combining digital precision and mechanical expertise to help dyeing plants achieve stable, high-value production for global performance brands.

Total automation

Logic Art has leveraged more than 30 years of engineering experience in the development of its Dye House Smart Total Solution, the world’s only end-to-end automation platform for dyeing and finishing plants. The modular system integrates auto-dosing, chemical distribution, energy management and predictive maintenance while seamlessly connecting with existing ERP systems.

Now adopted by dyeing factories in over 50 countries – including more than 70% of upstream suppliers to adidas – Logic Art’s technology ensures process stability, safety and sustainability. With regional service hubs in Vietnam, Turkey and Europe, the company continues to drive the industry’s transformation towards smart, data-driven and low-carbon production.

AI integration

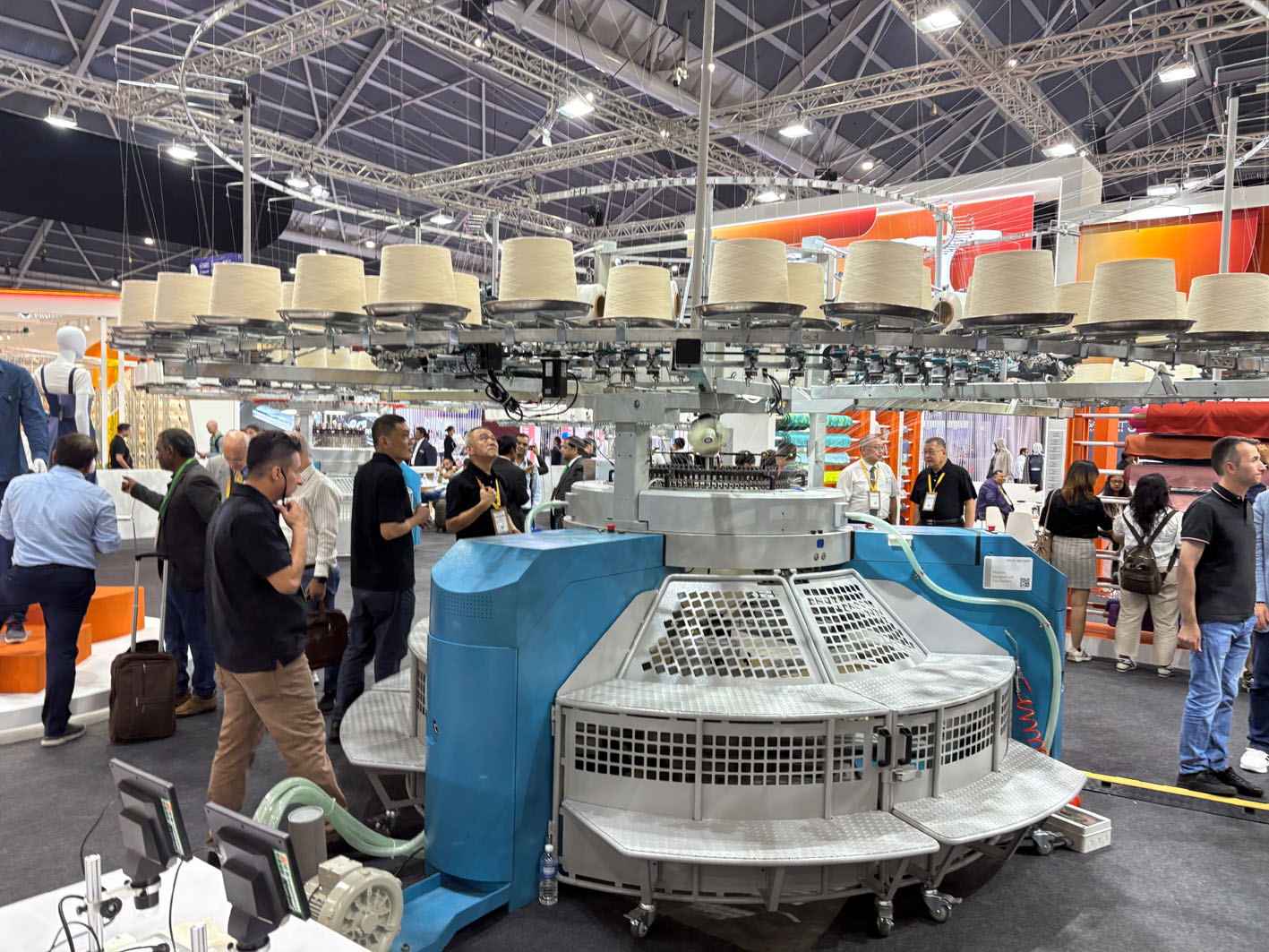

As one of the world’s top circular knitting machine manufacturers, Pailung unveiled its next-generation electronic jacquard circular knitting machine with smart knitting, marking a major milestone for AI-integrated textile manufacturing.

The new machine combines ultra-fine gauge precision and high-resolution jacquard capability, enabling the creation of intricate, multi-textured fabrics ideal for high-performance sportswear and premium fashion.

Integrated with real-time fabric defect detection, digital production management and automatic machine calibration, the smart knitting solution shortens setup time from hours to under 30 minutes while maintaining high speed consistency with energy efficiency.

By embedding AI and smart control into every step of the knitting process, Pailung is transforming knitting machines into intelligent production partners, redefining global standards of precision, flexibility and sustainability.

The showcase of these six Taiwanese textile machinery companies not only demonstrated advanced technologies but also Taiwan’s commitment to smart and sustainable manufacturing.

From knitting and dyeing to quality monitoring and automation management, each development is driving industrial upgrading and positioning Taiwan as a key force behind the global advancement of the textile and apparel industry.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more