New Camira fabrics awarded EU Ecolabel

Fibre absorbs between eight and 15 tons of CO2 per hectare of cultivation, while forests sequester between two and six tons per hectare.

11th May 2022

Innovation in Textiles

|

United Kingdom

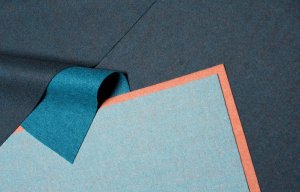

First launched in 2012, Camira’s Hemp-branded fabric range with impeccable eco-credentials and innate flame retardancy is made from an all-natural blend of wool and hemp fibres. Developed by Camira as part of its research into the use of plant stem fibres in textiles, Hemp has become one of the company’s most popular fabrics, selling thousands of metres since its introduction ten years ago.

Grown as an agricultural crop under licence from the UK government Home Office on a farm in England, the hemp plants used within Hemp are the Cannabis sativa strain which contains only minute amounts of the psychoactive substance THC. Proven to capture atmospheric carbon twice as effectively as forests, recent research by the Centre for Natural Material Innovation at Cambridge estimates that industrial hemp absorbs between eight and 15 tons of CO2 per hectare of cultivation, while forests sequester between two and six tons per hectare.

Part of Camira’s collection of fabrics made from bast fibres, Hemp is made using the long stem of the hemp plant. Sown from seed and reaching over three metres in height in just 120 days, Camira plants 45kg of seed for every hectare, which generates six tons of hemp straw. This in turn yields a ton of textile fibre, equating to 5,400 metres of fabric.

The process of separating the stem’s fibres for spinning into yarn begins with dew retting – a natural, sustainable way of allowing dew and rain to begin breaking down the tissues and pectins which surround the stem – which is then completed by mechanical decortication, during which the fine textile fibres are extracted from the heavier woody shiv commonly used in the creation of building materials and animal bedding. Once harvested, the hemp leaves are left behind to decompose and act as fertiliser for the following year’s crop. Requiring just 5kWh to produce 1kg of textile fibre – in comparison to 69kWh to produce 1kg of virgin nylon – the environmental benefits of hemp extend across its lifecycle.

“With sustainable design more important now than ever before, we are delighted that our Hemp fabric has stood the test of time and remains a beloved fabric in our portfolio,” said Jodie Padgett, senior innovator at Camira. “One of our proudest achievements, it is one of the most eco-friendly fabrics on the market, providing incredible environmental benefits, and is also beautiful in its aesthetics. With its natural composition visible in its appealingly weathered finish and multi-tonal colouration, we look forward to Hemp continuing to play a valuable role as a sustainable textile staple in commercial interiors.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more