Karl Mayer takes over ISO film cutting and stretching unit

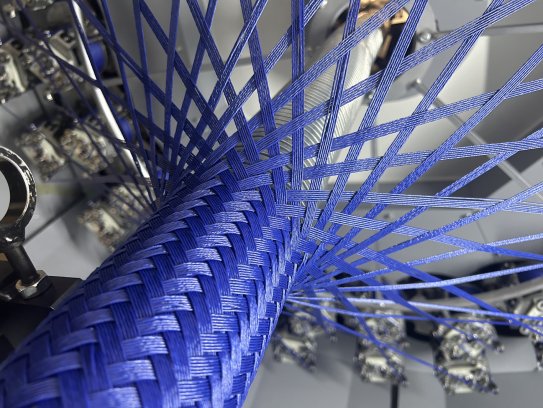

New servo drive can be used to control each deck individually on the new braiding machine.

4th August 2025

Innovation in Textiles

|

Albstadt, Germany

Mayer & Cie, headquartered in Albstadt, Germany, has just delivered its first MR-15 braiding machine with 48 carriers to a key customer.

Since moving its braiding machinery business from the USA to Germany, the machine builder has been consistently pushing ahead with the further development of its braiding technology with processes and components re-evaluated, documented and optimised.

One of the central innovations of the latest braiding machine is the servo drive, which can be used to control each deck individually. A soundproof booth has also been redesigned. At ITMA 2023 in Milan, the company also unveiled the SpeedBooster designed to significantly enhance machine speed and overall productivity.

The largest market for braiding machines is in China, where more than 50% of the braided hydraulic hoses manufactured worldwide are produced. The USA and Italy are also large markets.

Braiding machines with 48 carriers allow users to expand their range of inner hose diameters, which now range from 50-to-150 millimetres. The volume of spools with which the braiding machine is equipped remains the same – even if their absolute number increases to 48. For users, the combination means that they can process more material before a coil change is due.

“We are seeing an increasing number of inquiries for interlinked systems and in-line processes in which further units are to be integrated into the braiding line,” says Mayer & Cie braiding division manager Patrick Moser. “In addition, an expansion of our portfolio to include other machine types is being considered.”

While Mayer & Cie sells circular knitting machines in around 80 countries through local representatives, its braiding division operates directly and only works with local representative offices in selected markets. In exceptional cases, such as in India, both divisions share representation.

“We are pleased that we have now completed an MR-15 project with 48 carriers, which shows that we have fully achieved our goal of strengthening in-house development in the field of braiding machines,” says Mayer. “We are a company within a company and circular knitting machines have nothing in common with braiding machines, but the in-house process still the same. In itself, our business is project-driven and where such a project is realised geographically is of secondary importance.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more