Exploring options for UK textile-to-textile recycling

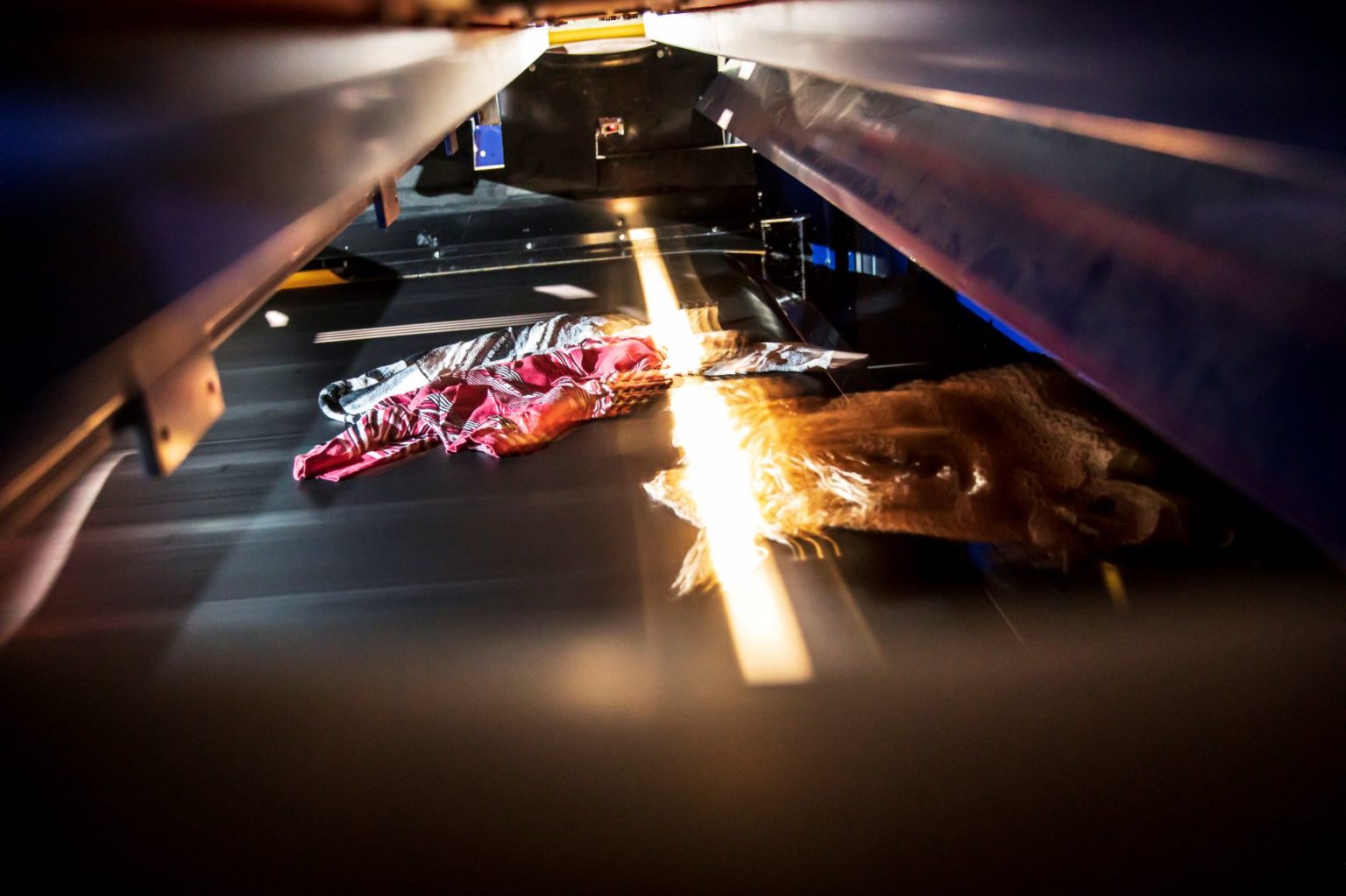

The new automated plant has a capacity of up to 4.5 tons per hour per line.

16th March 2021

Innovation in Textiles

|

Malmö, Sweden

Sysav Industri AB is now operating the world’s first fully automated sorting plant for textiles recycling in Malmö, Sweden.

The plant has been built and designed by Stadler, headquartered in Altshausen, Germany, and integrates four Autosort units built by Tomra, of Asker, Norway.

It is part of the government-funded Swedish Innovation Platform for Textile Sorting (SIPTex) project, which aims to develop a sorting solution tailored to the needs of textile recyclers and the garment industry.

Sorting textiles according to the various types of fibres they contain requires a high degree of precision. It is currently done manually, but the result doesn’t meet the requirements of recycling companies and the fashion industry. As a result, only a small quantity of discarded textiles is recycled and the potential for increasing it is enormous. The SIPTex project is exploring how to achieve the required quality through automation.

The plant is fully automated – people are needed only to start and stop the plant, feed the material in, and take the bales from the baler – that’s it

SIPTex

The plant is the third phase in the SIPTex project, and follows an initial theoretical study and, in phase two, the construction of a small pilot plant in Avesta, also designed and supplied by Tomra and Stadler in 2017. In this second phase, the project collected 700 tons of used textiles from recycling centres. Following a manual pre-sorting of reusable textiles, the waste material was fed into the Avesta pilot plant.

The main objective was to test the equipment’s capability to sort the textiles and identify any changes or optimizations to the process that may be required.

“Because automated textile sorting had never been done before, we were facing a challenging task we could only overcome by joining forces,” said explains László Székely, VP head of plastic applications at Tomra. “Thus, we relied on our longstanding and close partnership with Stadler. For the Avesta pilot we supplied an Autosort NIR VIS sorter, then four more for the Malmö plant.”

“Working on this pilot plant we realised that the feeding system is very important, that the hoppers and chutes need a special design because of the size of the textile material, and that the conveyors needed special belts,” added Stadler sales manager Urban Kozinc. “We also had to find the way to achieve a constant material flow, without peaks. And we learned that labelling on the textiles is not always 100% correct.”

Pre- and post-consumer

The new automated textile sorting plant in Malmö has a capacity of up to 4.5 tons per hour per line. The incoming material is delivered in bales, typically weighting 350 to 500 kg and includes both pre- and post-consumer waste.

The former consists of dry, industrial waste from textile producers such as clippings, yarn and rejects. The latter is made up of clothing and household textiles, which includes unsorted material from separate collection from sources such as recycling centres, and manually pre-sorted and industrial waste from textile leasing and rental services. The material is sorted whole and may contain buttons, zippers and other non-textile parts.

The project has included the supply of the dosing system, conveyor belts, NIR Optical Sorting Units, high-speed conveyor belts, bunker belts, baler, steelwork, electrical and control system, compressed air system and de-dusting system.

“In the Avesta pilot project we demonstrated that Tomra’s NIR sorting technology is capable of recognising and differentiating various types of textiles,” said Székely. “In the third phase, our objective was to ascertain that the system designed could successfully operate on an industrial scale, and that the output fractions can achieve the purity and recovery required for recycling and reutilization. There is no industrial-scale technology for recycling textiles without downcycling them, so we had to develop the complete sorting solution.”

At present, only little research is available on the recycling of textile fractions. In order to be effective in the sorting of pre- and post-consumer non-wearable textiles for recycling, automated sensor-based sorting is the key. In this project Tomra’s technology has proved efficient in separating different textile fractions by material type and colour.

“The plant is fully automated – people are needed only to start and stop the plant, feed the material in, and take the bales from the baler, that’s it,” Kozinc said.

“It’s re-assuring for us that even though automated textile sorting is a new technology, the base concept has been developed and refined by Tomra and Stadler in numerous existing plants,” said Sysav Industri construction project manager Olof Linde. “Building a world-unique facility requires stable and experienced partners.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more