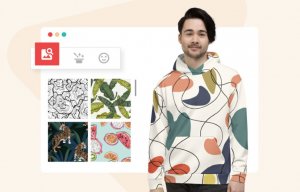

Printful teams up with Patternbank

Opinion

It sometimes seems as if every second person in Germany owns a Jack Wolfskin jacket, with its familiar paw logo. The brand – which employs 700 people in Germany and had 2013 turnover of €324 million – is tremendously popular in the country due to the quality and functionality of its garments, based around tried and tested material concepts like the Texapore range of waterproof shells. The brand’s popularity is growing elsewhere too. Despite a slight downturn in sales in its key markets of Germany and Austria in 2013 – in line with general trends – sales for the company in the UK were up by 45% and also in China by 25%.

11th February 2014

Adrian Wilson

|

Munich

It sometimes seems as if every second person in Germany owns a Jack Wolfskin jacket, with its familiar paw logo. The brand – which employs 700 people in Germany and had 2013 turnover of €324 million – is tremendously popular in the country due to the quality and functionality of its garments, based around tried and tested material concepts like the Texapore range of waterproof shells.

The brand’s popularity is growing elsewhere too. Despite a slight downturn in sales in its key markets of Germany and Austria in 2013 – in line with general trends – sales for the company in the UK were up by 45% and also in China by 25%.

According to European sportswear organisation Fedas, the total retail sales of all sports products (apparel and related gear) fell across Europe by 4% in 2013. The size of this market is estimated by Fedas to be now worth an annual €36 billion, but other forecasts put it higher.

The German market for sporting goods alone is estimated to be worth around an annual €7.2 by German retailers’ federation VDS (Verband Deutscher Sportfachhandel).

The overall fall in sales in 2013, however, is being put down to weather conditions rather than Europe’s ongoing economic problems and at the ISPO 14 show, held in Munich, Germany, from January 26-29, the overall sentiment was one of optimism for 2014.

ISPO 14 featured some 2,565 exhibitors and attracted more than 80,000 visitors from 100 countries, setting new records once again.

Among key apparel trends in evidence at the event – as part of the ongoing drive towards adding functionality and stretch for enhanced freedom of movement while shedding weight – were:

Without wishing to turn this into a free advertisement for Jack Wolfskin, however, it’s worth noting that the company is also something of a leader when it comes to social and environmental responsibility.

It has announced, for example, that by the end of 2014 it will remove PFOA from its production programmes and that half of all its apparel will be PFC-free two years earlier than planned.

By 2020, it plans to completely remove fluorine chemicals from all of its supplier’s production processes.

“We have distinguished ourselves as the first outdoor company with a concrete roadmap until 2020, outlining our plans to move away from fluorine chemicals, ban harmful substances from the supply chain and ensure transparent manufacturing among our suppliers,” claims CEO Christian Brandt.

At the end of 2013, the company published its third Supplier Social Report, in which it provided information about all of its suppliers and the social standards they adhere to.

“The year was over-shadowed by tragic accidents at factories in South East Asia,” says Brandt. “In our Supplier Social Report, we make it clear that we’ve been developing our suppliers for years and wish to achieve a high standard. But we’re also willing to stop working with certain suppliers – as has already been the case – if our efforts do not lead to an improvement for the people working for them.”

The Supplier Social Report is available on the Jack Wolfskin and Fair Wear Foundation websites.

In the ISPO 14 issue of the magazine published by the World Federation of Sporting Goods (WFSGI), Professor Aleksander Subic of Autralia’s RMIT University has some interesting observations to make about this.

“The relationships between the sporting goods brands and their supply chains are complex,” he says, “and investment in the development of the supplier’s capability is limited. The two appear to have different priorities. While the brands claim to be committed to product quality and corporate social responsibility, their suppliers are driven by the bottom line since they carry most of the risks associated with their manufacturing operations. Hence, they often only do what is required to satisfy the minimum brand requirements. In these circumstances, it is not clear how sporting goods will meet expectations for product stewardship and for achieving consistent social manufacturing across their supply chains without a more substantive investment in manufacturing.”

Jack Wolfskin is far from alone in increasingly taking on more responsibility for the supply chain that results in its profitable products, but it’s clear there’s much more that could be done by the industry overall.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more