Freudenberg to present solutions for energy storage at Techtextil

Materials are indispensable for the functioning of fuel cells.

21st October 2022

Innovation in Textiles

|

Weinheim, Germany

Freudenberg Performance Materials has concluded a high-volume, multi-year contract to supply high-performance nonwoven gas diffusion layers to a global automotive Tier One company.

Fuel cell technology is a major pillar of a successful energy transition and gas diffusion layers play a key role, being indispensable for the functioning of the fuel cell and having a significant impact on the performance of the fuel cell stack. Freudenberg already has more than 20 years of unique expertise in the development and production of gas diffusion layers for fuel cell applications in the mobility sector and for porous transport layers used in electrolyzers.

The global target applications of the customer are mid-sized and heavy commercial vehicles, as well as buses. The customer’s global fuel cell activities will accelerate the breakthrough of mass-produced fuel cell stacks.

Capacity expansion

“This high-volume, multi-year industrial-scale order is confirmation that the long-term investment in our technologies and the close cooperation with our customers is paying off,” said Dr Frank Heislitz, Freudenberg Performance Materials CEO. “As a result, fuel cell technology will become an increasingly important pillar of our business activities going forward.”

Freudenberg is currently expanding its production capacity at its Weinheim headquarters by installing additional lines and further investments are on the verge of implementation.

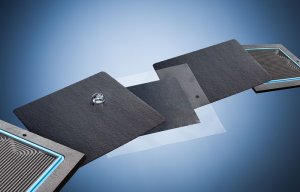

A fuel cell converts the chemical energy of hydrogen and atmospheric oxygen into electricity. Functionally-optimised gas diffusion layers are made of carbon-fibre based nonwoven and installed on both sides of a catalyst-coated membrane positioned in the middle of the fuel cell. They distribute hydrogen and oxygen evenly to the membrane and remove the electricity, heat and water generated by the CO2-free chemical reaction. They also protect the sensitive membrane and are optimised to suit the bipolar plate. A fuel cell stack is made up of several individual fuel cells.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more