3B awarded Norway’s export prize for 2017

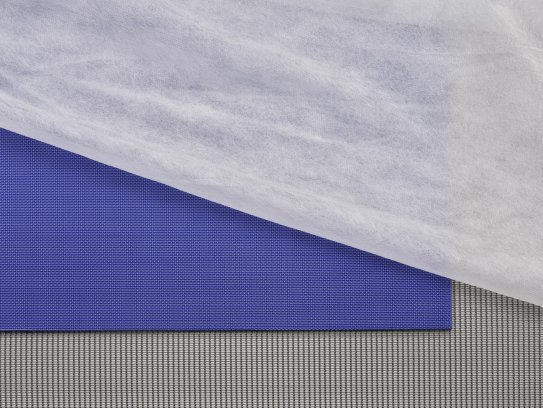

Process belts for impregnation and drying from a single source.

10th August 2021

Innovation in Textiles

|

Düren, Germany

In fibreglass mat production, dryer belts from the GKD Group, headquartered in Düren, Germany, set the standard worldwide – virtually all manufacturers trust in the evenness and cross stability of these woven metal belts.

With the expansion of its portfolio to include impregnation belts, GKD now supplies belts for the core processes of fibreglass mat production from a single source.

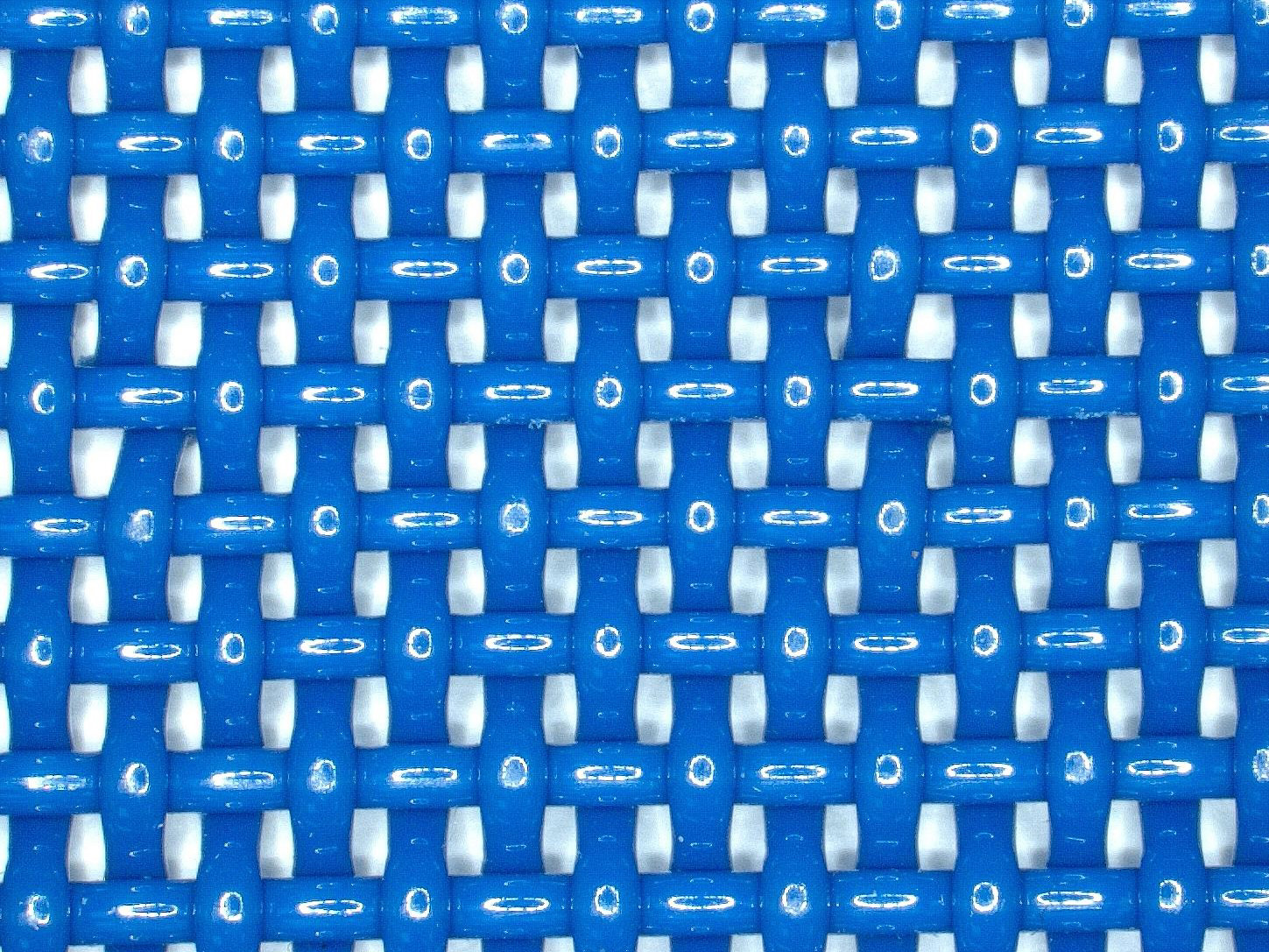

Impregnation belts have a decisive impact on the efficiency of the production process and the quality of the end product. Parameters such as the size of the mesh opening, the number of contact points and the type of weave are major contributors to the success of the process.

Based on market surveys, GKD developed three different types of belts for the impregnation processes. With their different sized mesh openings, they cover the entire range of requirements from 8/6.1 threads per centimetre to 11/9 threads per centimetre. Depending on customer specifications for the length and thickness of the glass fibres used – individual binder composition, process, and end product – GKD selects the ideal belt from this range together with the customer.

Established trust

GKD knows the processes, systems and products of virtually all manufacturers of fibreglass mats. As a result, it has established trusting relationships over many years, which it combines with decades of proven competence in the field of synthetic process belts.

In the challenging field of nonwovens production in particular, synthetic belts from GKD are considered a guarantee of efficiency and product quality.

The new impregnation belts from GKD for fibreglass mat production made of process-specific modified linear screen – also known as plain weave, are characterised by pore sizes and air permeability tailored precisely to the respective application and by a stable edge structure for accurate edge detection. Due to special process-dependent thermal finishing, their mesh design provides excellent running properties and the smooth surface ensures easy and gentle product release.

Available in all common widths for fibreglass mat systems with production speeds of up to 450 metres/minute, GKD is able to ensure short delivery times on the core market in the USA, via its subsidiary GKD USA

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more