All about touch – Huafeng’s new haptic cushion technology

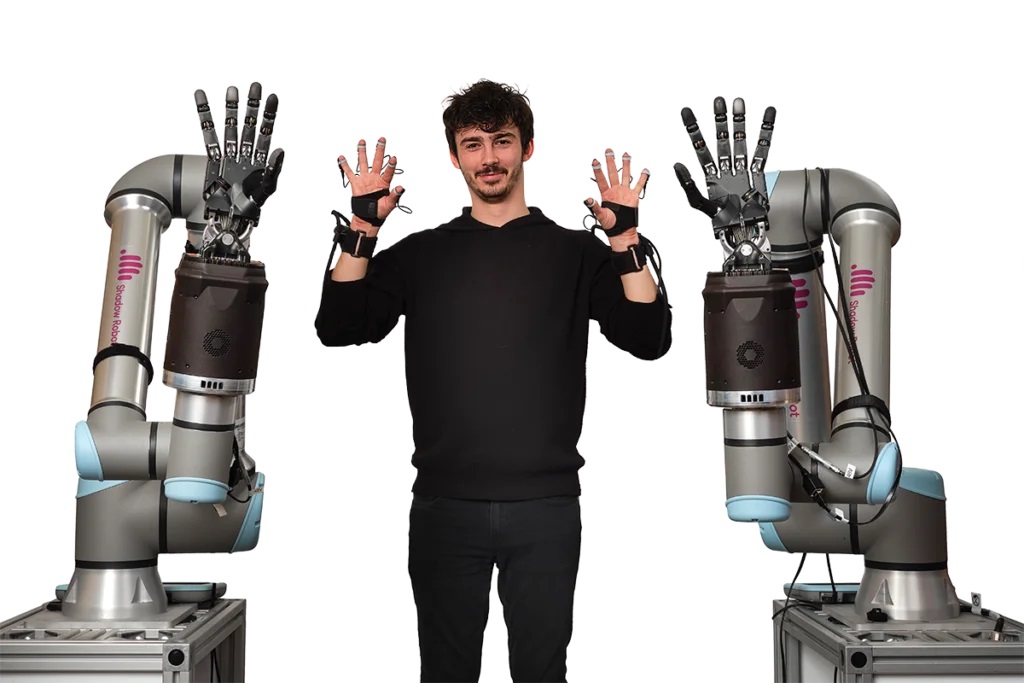

Robot is controlled via haptic gloves with fingertip sensors which can be relayed from over 5,000 miles away.

22nd November 2022

Innovation in Textiles

|

London

The Haptic Telerobot has been developed by London-based Shadow Robot to complete intricate tasks used in sterile manufacturing of vaccines and drugs.

Through a UK Research and Innovation (UKRI) open funding opportunity for ideas that addressed Covid-19, the company was awarded £586,026 in January 2021,

The award involved a collaboration with the pharmaceutical giant Pfizer and allowed Shadow Robot to further develop the Haptic Telerobot technology for use in isolator laboratories commonly used in the manufacturing of drugs and vaccines.

The robot – which is controlled via haptic gloves with fingertip sensors which can be relayed from over 5,000 miles away – was further developed to carry out intricate laboratory skills used in the manufacturing of vaccines and drugs such as pipetting and handling petri dishes, vials and zip-lock bags

The use of the Haptic Telerobot in this environment provides several benefits, including allowing critical workers to perform tasks at a safe distance, reducing the risk of disease spreading amongst staff and the contamination of vaccines and drugs by maintaining a sterile environment within isolators.

Vaccine and drug manufacturing is a key part of the healthcare supply chain and currently the pharmaceutical industry across the world is extremely stretched to meet this need.

Pharmaceutical companies have been busy researching new vaccines for Covid-19, yet there has also been a need to increase volume production for efficient large-scale manufacturing in the event of future pandemics.

Social distancing and quarantine measures were in force at the height of the Covid-19 pandemic and still remain in place in many vaccine and drug manufacturing environments.

This means only a limited workforce wearing full personal protective equipment can be present at any one time, reducing the efficiency of vaccine and drug manufacturing. Technologies that can aid new ways of working and allow adaptable, efficient scale-up of manufacturing are key to the healthcare supply chain.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more