Monforts coating competence at Techtextil 2019

A well known and existing coating technique which has been used for decades has recently been adapted by a UK company to provide a revolutionary way of coating hot melt materials in various forms and on to different substrates for wide-ranging industrial applications. The new technology is known as EKOKOTE. Web Processing (M/C) Ltd., based in Whaley Bridge in North West England, and collaborative partner Thom Engineering based in Blackburn, Lancashire, have t

25th November 2010

Innovation in Textiles

|

Whaley Bridge

A well known and existing coating technique which has been used for decades has recently been adapted by a UK company to provide a revolutionary way of coating hot melt materials in various forms and on to different substrates for wide-ranging industrial applications. The new technology is known as EKOKOTE.

A well known and existing coating technique which has been used for decades has recently been adapted by a UK company to provide a revolutionary way of coating hot melt materials in various forms and on to different substrates for wide-ranging industrial applications. The new technology is known as EKOKOTE.

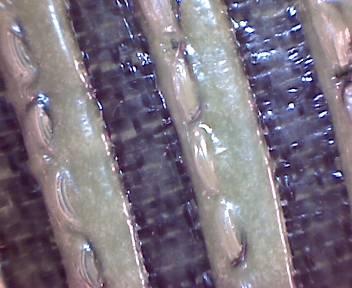

Web Processing (M/C) Ltd., based in Whaley Bridge in North West England, and collaborative partner Thom Engineering based in Blackburn, Lancashire, have taken an established and well known hot blade coating technology from the composites industry which is also used at ambient temp in the textiles, paper, nonwovens, film and foil industries and managed to successfully adapt it and turn it into a means of coating differing matrices used in the production of flexible materials and composites, including carbon fibre composites.

EKOKOTE technology can be either supplied as a standalone system or as a retrofitable system and is said to be a robust and accurate blade coating facility with a specially designed heated blade and tip. The heated blade is what sets the new technology apart from traditional blade coating.

The technique has been further improved by making the blade ‘live’ with a series of zoned heating elements each with its own temperature control allowing accuracy to within one degree centigrade to be maintained. Hot melt is presented to the coating head from extruders or bulk melting facilities of varying capacity depending on the end use and working width of the coating head.

Advantages cited by Web Processing for EKOKOTE include the fact that the process utilises materials that can be recycled easily. Currently many carpet backings use latex based coatings which are considered bad news in terms of recyclability and the new system allows the use of new hot melt alternatives to latex. The company also says that some of the hot melt materials outperform latex and the price is not considered prohibitive.

Investment levels in EKOKOTE coating technology are also said to be low in comparison to the alternatives. Hot roller coating systems for example, at the widths necessary are extremely costly and provide results that have been poor both aesthetically and in performance, Web Processing says. In some instances the new coating head equipment can be retrofitted into existing process lines, and as an option, within the arms of existing drying facilities.

According to Web Processing, tuft locking and lamination with carpets can be achieved in one pass with EKOKOTE and a high level of coating accuracy is achievable.

According to Web Processing, tuft locking and lamination with carpets can be achieved in one pass with EKOKOTE and a high level of coating accuracy is achievable.

The technology can also be used with waxes for paper applications and stripes and other coating patterns are easily produced. The resultant coatings can be used for applications such as noise reduction, lamination and reactivation. Anti- slip materials can also be coated.

Web Processing has been established in the coating and lamination industry for more than forty years and has more than 900 installations in 53 countries to date. Thom Engineering’s forte lies within the tufting industry; it mainly manufactures equipment used for the production of floor coverings, artificial turf, and some other specialised applications.

Thom Engineering is a company that is always looking for something new for its industry, and it immediately realised the benefits that would result from utilising the new technique to back coat and tuft lock carpets and turf, by replacing the current industry standard with recyclable hot melt materials derived from EVA (ethyl vinyl acetate) or olefin materials.

Web Processing is a unique equipment supplier comprising a team of both chemists and engineers, which allows it to drive the chemistry and tailor-make the coatings and adhesive systems employed when using interesting new approaches.

There are a number of traditional forms of coating and laminating techniques that fall within the company’s normal scope of supply, and apart from recent developments and success in the form of reactive polyurethane lamination technology and the composites industry, Web Processing is seeing a lot of interest in the products being manufactured using EKOKOTE technology and is treating the development with the same levels of enthusiasm and optimism generated when these other popular and pioneering developments were first introduced.

Progress with EKOKOTE has been brisk and Web Processing has already converted two major UK flooring producers, helping redevelop their old bitumen and PVC backing facilities to incorporate the new method. In addition a major client in India had a line converted to EKOKOTE just last month.

The company has also achieved FIFA approval with a specific product in the artificial turf sector and conducted trials for clients all over the world including the UK, Australia, South Africa, South America, Europe and Egypt.

A 6 metre wide line has recently been installed at a company involved in the geosynthetics industry using a similar relatively low cost system in conjunction with an EVA hot melt.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more