Navis TubeTex teams up with Fibroline

Any type of binder or functional powder can be processed on the system which uses no solvents and consumes little energy.

18th March 2021

Innovation in Textiles

|

Limonest, France

Fibroline, based in Limonest, France, has developed strong expertise in the impregnation of textiles and nonwovens impregnation with its dry powder impregnation solutions.

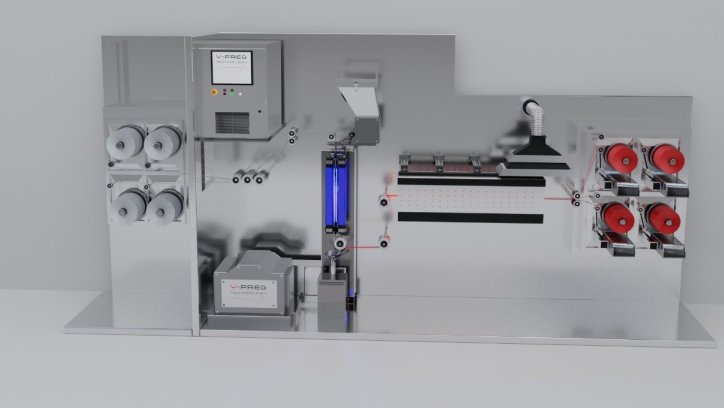

Following a two-year research programme an innovation team at the company hasnow developed and patented a new solution for yarns and composite tapes impregnation called Y-Preg.

The process remains closely linked to the use of a high voltage alternating electric field for charging and distributing particles homogeneously into the porosities of multifilament yarns or UD reinforcing fibres.

Any type of binder or functional powder can be processed on the system which uses no solvents and consumes little energy, significantly reducing the overall manufacturing environmental footprint.

“Our objectives are to assist our customers with the powder selection, powder blending, fixation parameters in order to help them identify the added value our new solution can bring to their applications,” says innovation manager Sofien Bouzouita, who is in charge of the Y-Preg business development.

A brand-new pilot line has been installed at Fibroline’s innovation centre, in line with flexible peripheral equipment to carry out semi-industrial runs with customers, prior to final technology transfer. Several partners have already attended demonstrations on this line, or via video conferencing to overcome the constraints linked to the current crisis.

Due to a very wide range of potential new products, Fibroline decided to establish strategic cooperation agreements per market segment, providing them to companies driven by innovation a technological advance in their field with the introduction of greener and unique products thanks to a disruptive solution.

“The Y-Preg technology opens new business opportunities for various markets and Fibroline needs its partners’ expertise to turn those ideas into successful industrial solutions,” said CEO Jérôme VILLE. “This is the reason we decided to join forces with market leaders in their fields, to create synergies between their specific skills and our technological know-how.

Fibroline engineers are now closely investigating the potential of the new Y-Preg solution for impregnating medical, dental or implantable yarns with new antimicrobial, antiseptic and haemostatic additives.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more