New Comez machine for sportswear and technical applications

Comez, a global leader in advanced narrow fabric technology has launched a new electronic double needle bar warp knitting machine, DNB/EL-1270, for the manufacture of a wide range of technical and apparel fabrics including: Technical applications - Netting for sports equipment and the food industry, high resistance ribbons in special fibres, ribbons and fabrics for geotextiles applications, automotive, building and industrial sectors Medical applications - Tub

15th September 2009

Innovation in Textiles

|

Cilavegna

Comez, a global leader in advanced narrow fabric technology has launched a new electronic double needle bar warp knitting machine, DNB/EL-1270, for the manufacture of a wide range of technical and apparel fabrics including:

Comez, a global leader in advanced narrow fabric technology has launched a new electronic double needle bar warp knitting machine, DNB/EL-1270, for the manufacture of a wide range of technical and apparel fabrics including:

Technical applications - Netting for sports equipment and the food industry, high resistance ribbons in special fibres, ribbons and fabrics for geotextiles applications, automotive, building and industrial sectors

Medical applications - Tubular elastic netting, emergency bandages and dressings and disposable underwear

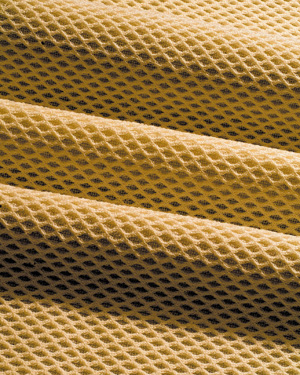

Women's apparel - Mesh stockings, pantyhose and fashion fabrics

The new Comez DNB/EL-1270 features a 1270 mm working width and comes in a range of gauges from 5 to 18 needles per inch. The machine uses individual latch needles and Comez says it can work with any type of yarn. It is equipped with 12 pattern guide bars with electronic control and knockover sinker groups can be supplied on request.

The electronic drive of the yarn feeders and the fabric take-down allows for the possibility of different stitch density values (stitches/cm) on one single product, as well as different values for weft or warp feeding and elasticity.

The machine is fitted with the new Data Control Controller which manages all necessary machine functions, monitors production data and allows for the realisation of lengthy pattern repeats: the number of lines for each pattern can reach a value that is just about unlimited, Comez claims.

The machine is fitted with the new Data Control Controller which manages all necessary machine functions, monitors production data and allows for the realisation of lengthy pattern repeats: the number of lines for each pattern can reach a value that is just about unlimited, Comez claims.

Comez’ Fiorenzo Sanzani says: “The electronic programming of the pattern guide bars allows articles with different structures to be produced without interruption, and the fabrics obtained feature a good three-dimensional consistency, difficult to obtain on single-needle bed machinery for traditional fabrics.”

“Thanks to the presence of two needle bars and the unique evolution of the pattern guide bars, it is possible to obtain ‘double face’ fabrics, with identical structure and specifications on both sides: the fabric doesn't actually have a front or reverse side. This is a very important characteristic in the production of articles such as knitted nettings and technical fabrics. However, it is also possible to differentiate the appearance of the two sides of the fabric, for example with a mesh structure on one face and a plain close-knit structure on the other”, Sanzani added.

According to Comez, with regard to articles in netting, both rigid and elastic, they can be created either flat or in a tubular form. In the flat form, the stitches dimensions can be set from a few millimetres to several centimetres: the adjustment can be made without interruption and the structure can be either simple or reinforced at crossover points by a ‘super knot’. In the tubular form the structure can be with simple mesh, with very open mesh, e.g. for the production of mesh wrapping bags for fruits and vegetables, and with ‘woven’ mesh, such as for the production of tubular netting for medical uses).

“With technical fabrics, one of the most interesting possibilities is that of spacer fabrics which basically comprise two distinct fabrics, constituting the two faces of the whole (even with different appearances), connected by yarns with good flexural rigidity properties, so that the two faces are kept at a certain distance by the connecting yarns. Structures obtained using this process are thick and have good elasticity to pressure (absorption effect). The electronic programming allows the production of fabrics with alternating three-dimensional and flat areas to be made easily”, says Fiorenzo Sanzani.

“With technical fabrics, one of the most interesting possibilities is that of spacer fabrics which basically comprise two distinct fabrics, constituting the two faces of the whole (even with different appearances), connected by yarns with good flexural rigidity properties, so that the two faces are kept at a certain distance by the connecting yarns. Structures obtained using this process are thick and have good elasticity to pressure (absorption effect). The electronic programming allows the production of fabrics with alternating three-dimensional and flat areas to be made easily”, says Fiorenzo Sanzani.

Given the vast range of fabrics that can be made and yarns that can be used, the Comez DNB/EL-1270 can also be used for mixed compositions. The machine can be fed yarns from creels only, creels and beams combined or beams only. The yarn feed can also be provided with electronic feeders secured to the machine or by floor-standing external electronic feeders. The collection system for the finished product can be tailored to the user’s requirements and available space.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more