-300x192-cropped.jpg)

Restoring drinking water supply in downtown Amsterdam

The material soaks up and purifies seawater.

7th July 2025

Innovation in Textiles

|

Hong Kong

Researchers at Hong Kong Polytechnic University have developed an aerogel-based material with long, microscopic air pockets that exploits sunlight and a simple plastic cover to turn saltwater into freshwater.

A proof-of-concept test outdoors has successfully produced potable water in natural sunlight in a step towards low-energy, sustainable desalination.

This isn’t the first time scientists have created spongy materials that use sunlight as a sustainable energy source for cleaning or desalinating water. A loofah-inspired hydrogel with polymers inside its pores, for example, was tested on chromium-contaminated water and when heated by the sun quickly released a collectible, clean water vapour through evaporation.

While hydrogels are squishy and liquid-filled, however, the new aerogels are more rigid, containing solid pores that can transport liquid water or water vapour. Aerogels have been tested as a means of desalination, but they are limited by their evaporation performance, which declines as the size of the material increases.

The aim of the researchers in Hong Kong was to design a porous desalination aerogel that maintained its efficiency at different sizes.

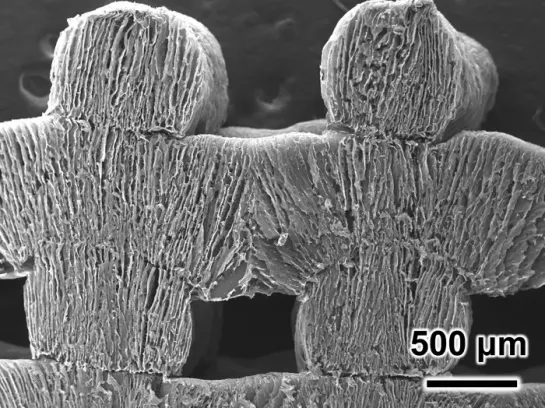

To achieve this, they made a paste containing carbon nanotubes and cellulose nanofibres and then 3D-printed it onto a frozen surface, allowing each layer to solidify before the next was added. This process formed a sponge-like material with evenly distributed tiny vertical holes, each around 20 micrometres wide. The researchers tested square pieces of the material, ranging in size from 1-8cm and found that the larger pieces released water through evaporation at rates as efficiently as the smaller ones.

In an outdoor test, the researchers placed the material in a cup containing seawater and it was covered by a curved, transparent plastic cover. Sunlight heated the top of the spongy material, evaporating just the water, not the salt, into water vapour. The vapour collected on the plastic cover as liquid, moving the now clean water to the edges, where it dripped into a funnel and container below the cup. After six hours in natural sunlight, the system generated about three tablespoons of potable water.

The researchers are now looking to scale up the development, which was reported in the American Chemical Society’s Energy Letters.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more