Uster Tester celebrates its 70th anniversary

The company explains the history behind developing a technology aimed to help manufacturers produce flawless yarn.

_IMG_4902-612x408-boxed.jpg)

29th September 2015

Innovation in Textiles

|

Uster

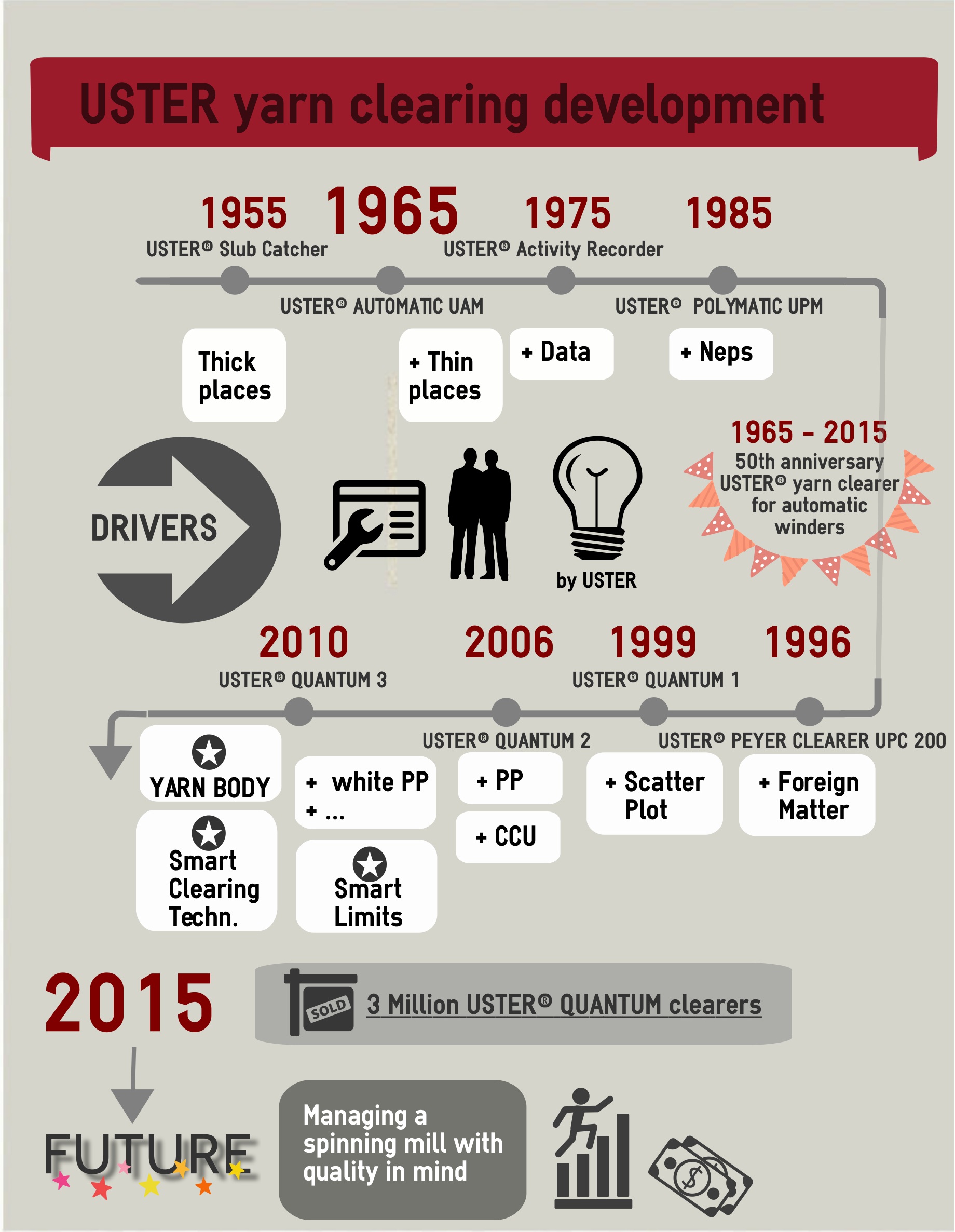

Yarn clearing technology has come a long way in the 50 years since the first system for automatic winding was marketed by Uster. Quality has always been a big issue for both spinners and fabric manufacturers, but it was not until the early years of the 20th century that the first steps were taken towards automatic control of yarn quality during production, according to the manufacturer.

Uster Technologies, a leading high-technology instrument manufacturer, offers the company’s latest Uster Quantum 3 clearers, with a range of innovative features designed to help mills to produce the right yarn quality with optimum productive efficiency and profitability. The company also explains the history behind developing a technology aimed to help manufacturers produce flawless yarn.

A group of spinning mills located along a small Swiss river, the Aabach, not far from Zurich, was anxious to find a solution for recurring thick places in their yarns. They began discussing the problem with a company in the nearby city of Uster: the then Zellweger Uster, the forerunner of the company which became Uster Technologies in 2003.

The initial result, in 1952, was a patent filing for a Thread Cleaning Device by the Uster company. This was a mechanical system for detecting thick places on manual winding machines, across a limited range of yarns. Launched as a Slub Catcher in 1955, this device was the first Uster yarn clearer.

New demands

The first yarn clearers were for manual winders only. The advent of the more efficient automatic winding systems presented new demands for clearer developers, and in 1965 Uster launched its first system for this process.

The Uster Automatic UAM B1 – celebrating its 50th anniversary this year – was installed on several of the leading automatic winding machine brands. It was still limited to clearing only thick places, until the next model, the UAM C1 appeared with the capability to eliminate thin places as well.

Even with these developments, by the 1970s yarns were still suffering from quality issues. But this was the beginning of the Information Age, and it brought important new potential for improvements in textile quality control, the company reports.

Uster realized that data about clearer cuts at the winder and machine standstill times could be a valuable aid to mill efficiency. In 1975, the company launched the Uster Activity Recorder for its yarn clearers. This was the first true data system for yarn clearing, the ancestor of the technology spinners now regard as essential in the modern winding room.

The next major step was the spread of microprocessor technology, which took yarn clearing beyond just detection of thick and thin places.

The final hurdle in defect removal was the detection of polypropylene – and this was overcome with the first generation of Uster Quantum yarn clearer in 1999. By this time, yarn clearing was already acknowledged as essential for quality monitoring to avoid costly claims, but its benefits in enhancing production efficiency were also becoming significant. The Uster Quantum 2, with its Central Control Unit (CCU) display of key data on spinning and winding progressed this trend.

R&D goals for the Uster Quantum 3 focused on a clear vision: to allow spinners to create the perfect yarn for their customers at the lowest possible cost. Advanced sensor technology and Uster’s expertise in data generation led to a series of genuine innovations in fulfilling this vision.

Smart Clearing Technology, based on built-in knowledge, guaranteed optimum results for each yarn application. The Yarn Body concept provided an instant visualization of yarn quality parameters and variations. And the Smart Limits feature allowed users to customize clearer settings at the push of a button. These developments break new ground in terms of detection capabilities, intelligent operation and user-friendliness, according to the manufacturer.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more