-300x192-cropped.jpg)

A&E expands sustainable offering with Repreve

Software can provide reports on the denim garments produced for each customer or brand.

13th November 2023

Innovation in Textiles

|

Italy

During a recent webinar, Revisiting ITMA 2023, which is available to view on the ITMAconnect website, Simon Guilliani, global marketing director at Candiani – Europe’s largest denim manufacturer – cited Tonello’s Metro software as a potential game changer in industrial laundries for the finishing of denim jeans and garments.

Metro measures a laundry’s actual consumption – of water, energy, products – and enables centralised management and automatic analysis of all machines.

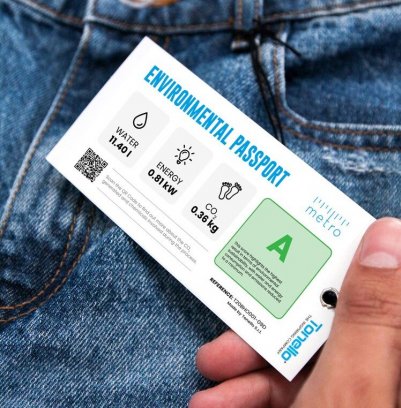

As a digital platform it enables users to control, optimise and increase the level of sustainability and efficiency of both production processes and products, creating an ‘environmental passport’ based on real, transparent, automatic and non-manipulable data.

It can provide reports on the garments produced for each customer or brand and the related data of the baths and processes carried out, and enables each batch and even individual garment to be tracked.

“The industrial laundry is where the magic happens and where most of the creativity takes place when it comes to the wash-down of the jeans and each laundry does it differently and has its own signature and different ways of using chemicals,” Guilliani said. “Being able to rationalise that and to put it into certain metrics is something extremely helpful, in order to have data that gives you a very tangible idea of the impact.

“Digitalisation not only gives you an integrated overview of real time data on a B2B level, but also creates very valuable information for the B2C level for the brands who then actually purchase those garments and have to also respond with production data, which is a matter of compliance that is being discussed in the EU and the USA right now.

“Digitalisation, in simple terms, allows measurement and sustainability is measurement. It makes it possible to have two pairs of jeans with the same aesthetics and look and quickly discover that one had a much lower impact in its production than the other.

“The European Commission has a goal to reduce the carbon footprint of products by 55% by 2030, which is a huge goal to reach where we have to work collaboratively. We’re trying to do our own innovation, but we’re also looking for industrial partners who can complete the cycle.

“There is going to be a huge shift in the garment industry in the next five years. A lot of things will have to change and brands will have to adapt. The old way of making garments is completely not aligned with these new goals,” Guilliani concluded.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more