Expert treatment for sensitive synthetics

Fong’s Europe will be providing details of its new Then Supratec LTM hydraulic long-tube dyeing machine at this year’s ITMA 2019.

7th May 2019

Innovation in Textiles

|

Schwäbisch Hall

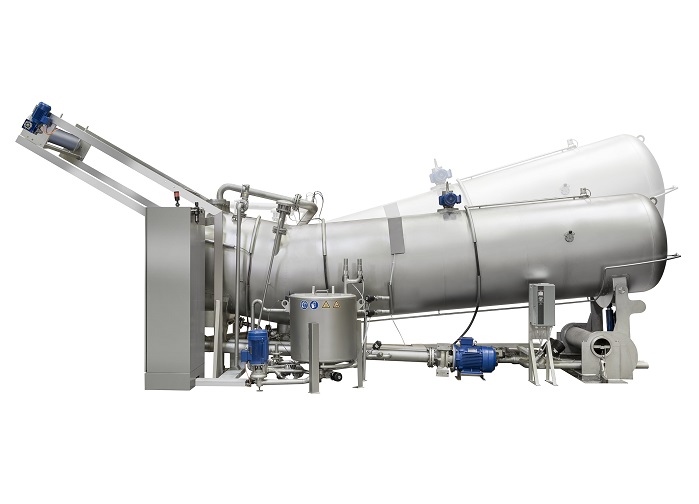

The new Then Supratec LTM hydraulic long tube dyeing machine. © Fong’s Europe

Fong’s Europe, a member of CHTC Fong’s International Group, will be providing details of its new Then Supratec LTM hydraulic long-tube dyeing machine at this year’s ITMA 2019 trade fair for textile machinery that takes place in Barcelona from 20-26 June.

This machine is distinguished by the ability to vary the angle of the Then Flexkier for either dry (jet) or wet (overflow) mode dyeing, in order to optimise the dye liquor ratio – from 1:15 down to 1:4 – depending on the materials being dyed, the manufacturer explains. This is said to translate into considerable savings in auxiliaries, water and energy.

The Supratec LTM is suitable for the treatment of both woven and knitted fabrics ranging from the most sensitive articles to heavyweight materials within the weight range of 25 g/lm to 380 g/lm and operates at very low tension due to the extremely low lifting height between the variable nozzle and the plaited fabric. “Existing Supratec machines on the market are providing excellent performance for a wide range of delicate synthetic fabrics, from polyester to polyamide with high content of elastane,” says Fong’s Europe Director of Sales and Marketing Richard Fander.

The new Then Supratec LTM hydraulic long tube dyeing machine. © Fong’s Europe

“Heat-setting can often be avoided, which improves the handle of the material and saves costs and the lengthwise-elongation of the fabric being treated is lower than on winch-driven machines.”

The machine’s automatic plaiting system for one and two transport tubes is equipped with a frequency-controlled driving motor for variable speed adjustment and eliminates the danger of any fabric entanglements, he adds.

Each kier has a capacity of up to 230kg, again depending on the fabric being treated, and operating speeds are from 80 up to 600 metres a minute.

This year, the company, which is based in Schwäbisch Hall, Germany, is celebrating the 100th anniversary of its flagship Then brand for advanced dyeing technology. The company will introduce the new Then Smartflow TSF hydraulic high-temperature dyeing machine in Barcelona. “This is distinguished by a range of patented new features and designed to achieve the lowest possible energy and water consumption rates available on the market for jet dyeing,” the company explains.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more