Autoneum optimises production process for floor insulators

Prime-Light will be presented to the public for the first time at the International Automotive Acoustics Conference in Zurich this month.

19th June 2015

Innovation in Textiles

|

Winterthur

With Prime-Light, Autoneum, the leading producer of vehicle acoustics and thermal management systems, is launching a new technology for inner dashes and floor insulators that is designed to offer excellent shapeability, light weight and a high acoustic performance.

Prime-Light will be presented to the public for the first time at the International Automotive Acoustics Conference in Zurich, Switzerland, from 23-24 June. The renowned and traditional specialist vehicle acoustics event has been staged under the scientific leadership of Autoneum for more than 40 years.

Prime-Light is the latest further advancement of Autoneum’s Ultra-Light technology and represents a quantum leap in terms of innovation within the segment for inner dashes and floor insulators for vehicles, the company reports.

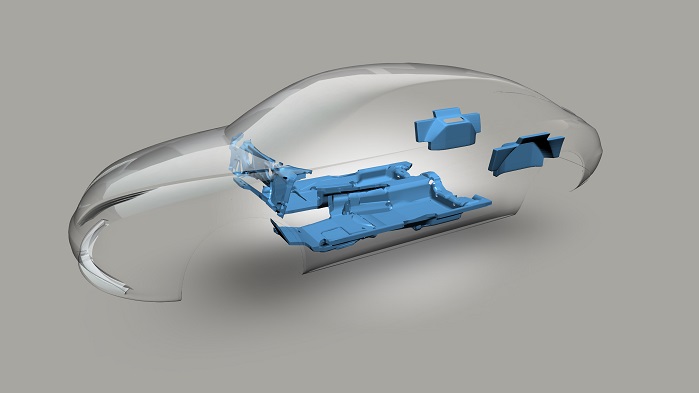

Compared with previous versions of Ultra-Light, Prime-Light components can be pressed into a wide variety of different shapes and sizes. This way they are said to adjust optimally to the individual body-in-white shapes and take account of increasingly complex production processes in vehicle construction. Thus, Prime-Light can now also be applied in vehicle models where Autoneum’s Ultra-Light technology could not be used so far.

Prime-Light also convinces with a light weight while maintaining the same level of acoustic protection, according to the manufacturer. Thanks to a 30% weight reduction compared with previous models, Prime-Light-based inner dashes and floor insulators save more than 2 kg of weight in average.

Automobile manufacturers and end consumers can equally benefit from this weight reduction, Autoneum believes. If, for instance, the weight of a vehicle is reduced by 100 kg by means of lightweight materials, this leads to a 0.55 l reduction per 100 km driven in gasoline consumption and almost 13 g fewer of COâ‚‚ emissions (based on overall consumption of 5.5 l per 100 km in average).

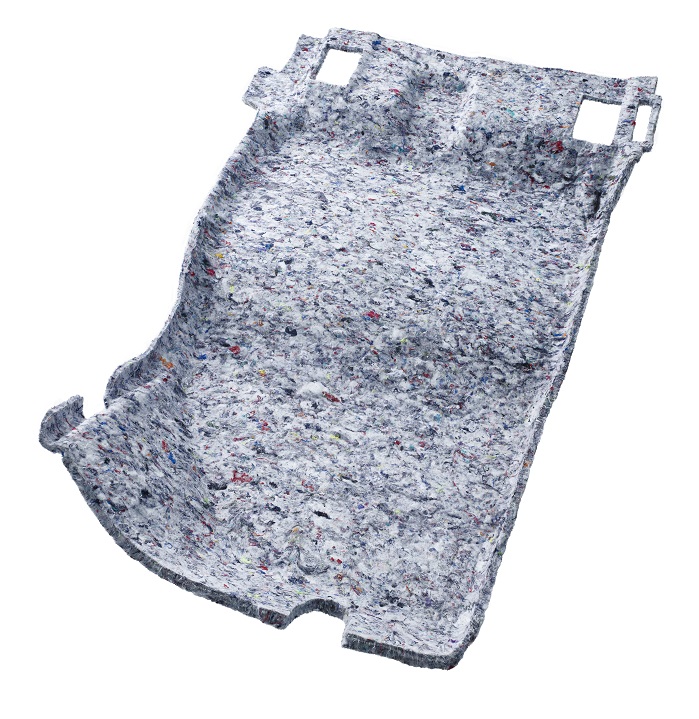

Prime-Light-based inner dashes and floor insulators consist of thermoplastic cotton felt compounds, in which the share of recycled materials amounts to up to 50% depending on the application-specific composition.

In order to achieve the greatest possible acoustic protection, Autoneum already models and analyzes the ideal density and thickness of these components during the design phase of new vehicle models. Prime-Light will be produced in series for models of US OEMs in North America and China next year.

Prior to the market launch of Ultra-Light in 1998, insulations made of heavy layer foam were largely used in vehicle construction to curb noise. Autoneum introduced a new solution with the launch of Ultra-Light. With the new technology, vehicle noise has not been merely insulated respectively quietened but absorbed.

While sound insulating components block noise and prevent it, for instance, from seeping through from the engine bay to the passenger compartment, sound-absorbing components swallow unwanted noise, the company explains.

Products for the absorption of noise, such as inner dashes and floor insulators, therefore, are made of lightweight textile materials rather than heavy layer foam, thereby significantly reducing the vehicle weight. Autoneum produces around 19 million Ultra-Light components throughout the world each year for over 100 vehicle models of more than 20 car brands.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more