Evolon New Generation receives ECARF seal of quality

For greater comfort, Evolon super-microfilament fabric is breathable, light, soft and drapable, the company explains.

12th January 2017

Innovation in Textiles

|

Colmar

Pillows and duvets made of feathers and down are extremely comfortable and provide a feeling of top of the range bedding. But this sensation of well-being can quickly be spoilt by escaping down and dust, not to mention the discomfort generated by the feathers with their sharp tips poking through the fabric, Freudenberg Performance Materials reports.

Super-microfilament textiles – the latest in the company’s Evolon product range – are the manufacturer’s new technical and eco-friendly solution for pillows, duvets, sleeping bags and other quilted products filled with feathers and down.

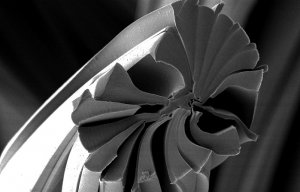

Thanks to its structure of closely entangled super-microfilaments, which are up to 200 times thinner than a human hair, weighing less than 130gsm, the new Evolon variant is a high-density cover fabric which is designed to prevent any loss of filling from even the finest layer of down. The textile is also said to make it possible to mask dark feathers or those that are a little too thick and prickly.

For greater comfort, Evolon super-microfilament fabric is breathable, light, soft and drapable, the company explains. The moisture generated by perspiration during sleep is quickly evacuated. The moisture management properties and downproof performance have both been validated by Germany-based Hohenstein Textile Testing Institute.

Evolon also acts as a natural physical barrier against dust mite allergens. As a result, Evolon also filters residual dust from feathers and down which could escape from the pillow or duvet, helping improve bedding hygiene.

The filtration quality of Evolon is strengthened with each washing, according to the manufacturer. Unlike traditional textile covers with weave that can loosen and allow the down to escape, repeated washing is said to cause the multidirectional, microfilament structure to tighten up, thereby reinforcing the barrier effect provided by Evolon.

Producing Evolon does not require the use of any solvents and is said to minimise water consumption quite spectacularly when compared to cotton-based textiles commonly used to make pillows and duvets containing feathers and down. Within this context, it is estimated that the Evolon production consumes about 400 times less water, depending on the type of competing product.

Evolon is manufactured in Europe in accordance with ISO 9001, ISO 14001 for respecting the environment, ISO 50001 for its continuous programme of reduction in energy consumption and OHSAS 18001 for employee health and safety.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more