BCF S8 Tricolor meets need for trend towards multiple colours

The focus of the Oerlikon Neumag booth will be on solutions for the sustainable manufacture of carpet yarns.

18th January 2016

Innovation in Textiles

|

Neumünster

Oerlikon Neumag, a specialist in solutions for all important nonwoven production processes, is presenting its diverse range of products and services at this year’s Domotex trade show for carpets and flooring that takes place in Hanover, Germany, from 16-19 January.

The focus of the Oerlikon Neumag booth will be on solutions for the sustainable manufacture of carpet yarns. The company will demonstrate that the trend of sustainability is also a major focus in BCF yarn production, by the exemplary success of its RoTac tangling unit.

Since the market launch of the RoTac3 as the new tangling unit for the BCF S+ system a year ago, almost 90% of all new sales have been equipped with the rotating tangling unit.

The retrofitting business with the component is also operating well, according to Martin Rademacher, Oerlikon Neumag Sales Director. “For us, this is a signal that energy costs are playing an increasingly important role in BCF production,” he said.

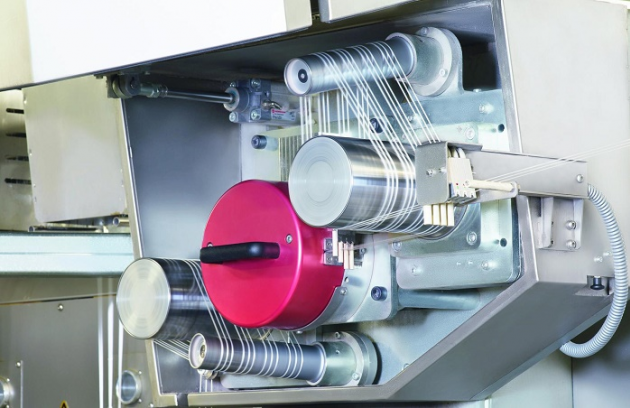

The RoTac has been deployed as the tangling unit in the single-end Sytec One system since 2012. Meanwhile, virtually all Sytec One systems are sold with the RoTac tangling unit. To this end, the further development of the unit to create a three-end system was a logical step, the company reports.

With its range of systems, the market leader from Neumünster covers a variety of requirements of carpet yarn manufacturers, something that is demonstrated by the high demand for the BCF S+ and Sytec One systems, the manufacturer reports.

While the S+ is a convincing solution for commercial applications, the Sytec One is said to be particularly good for demanding production processes due to its monofilament character.

“With the S+ and Sytec One, were are extremely well positioned within the BCF market worldwide. We can cover practically all customer requirements with these two systems,” explained Martin Rademacher.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more