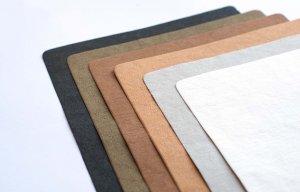

Vegan certification for Texon Vogue

Opinion

Steven Bethell is co-founder of the Bank and Vogue group of companies that includes the Beyond Retro vintage shops in London.

9th October 2019

Marie O'Mahony

|

London

Steven Bethell is co-founder of the Bank and Vogue group of companies that includes the Beyond Retro vintage shops in London. A pioneer and tireless innovator in post-consumer textiles, I caught up with him at the WEAR2019 conference in Toronto this week to ask about his work in global and UK retail in particular, as well as a new product launch with Converse and scaled manufacturing for the post-consumer textiles sector.

Steven Bethell is co-founder of the Bank and Vogue group of companies that includes the Beyond Retro vintage shops in London. A pioneer and tireless innovator in post-consumer textiles, I caught up with him at the WEAR2019 conference in Toronto this week to ask about his work in global and UK retail in particular, as well as a new product launch with Converse and scaled manufacturing for the post-consumer textiles sector.

In the report Facts and Figures about Materials, Waste and Recycling issued by the US Environmental Protection Agency (EPA) in May this year, 10.5 million tons of Material Solid Waste (MSW) textiles went to landfill in 2015. This is an increase from 9.96 million tons the previous year and accounts for 7.6% of all MSW landfill. “Americans buy 450 million pairs of yeans very year,” according to Steven Bethell, “a large portion are [sizes] 40-42 – what do you do with those sizes!” The technology used to recycle old textiles into new fibres has been described by the Wall Street Journal as “embryonic”. I began by asking Steven if he thinks this is an accurate assessment.

“We [at Bank and Vogue] deliver a quarter of a million pounds of post-consumer textiles to re:newcell, that is one really big fat embryo!” Mr Bethell sees the industry and capability for scale as growing with the emergence of innovative companies like re:newcell who are based in Kristinehamn, Sweden. The company was founded in 2012 following on research undertaken at the Royal Institute of Technology (KTH) in Stockholm, where they sought to find more efficient ways to decompose cellulose and later viscose also to produce bioethanol.

By 2014 re:newcell had managed to create a dress made from chemically recycled denim was shown on the fashion catwalk and by 2017 the first production plant had opened with a capacity to produce 7,000 tons of Circulose pulp per annum. What the process offers is the possibility to convert cotton and other natural fibre textile waste into a new fibre in a continuous process of renewal and thereby closing the loop.

Bringing together the raw material, the post-consumer textiles in an effective and efficient manner is where the know-how of Bank and Vogue comes in. On the use of specific technology by Bank and Vogue Steven Bethell points instead to a centralised processing system as being the key to their success. Scale makes it possible to bring the post-consumer textiles to just a few centres and handle the sorting and handling. Putting back into the manufacturing process is a small part of their business, with vintage garments resold where possible in shops and online. As consumer interest has grown so too has work with some of the biggest brands on the high street, keen to advance their own sustainability platforms.

Seventeen years ago Bank and Vogue became a hip presence on the London high street with its Beyond Retro shops. Retail alternatives at that time focused on charities such as Oxfam, who sold donated clothes alongside books and other household products. Beyond Retro attracted a predominantly young consumer group, with clothes and footwear carefully curated. While the young consumer visiting the charity shop might bump into their mother or grandmother, there was little chance that would happen in Beyond Retro. Fast forward seventeen years and the announcement this week of a new initiative with the John Lewis Partnership. The mainstay of British retail was established in 1925 with its mantra of Never Knowingly Undersold reinforced with three commitments across all brands to always be fair, look to transform lives and never be wasteful launching a pilot buy-back service designed to reduce clothing landfill waste in 2018.

So how did we get to this point? In a blog posting on the Bank and Vogue website in July 2019 offers some clue: “The first differentiating factor about the UK is that the whole country has a healthy recycling culture. Almost 60% of people living in the UK have a habit of textile recycling.”

The UK sends out around 700,000 used items of clothing to textile banks, charitable organisations and recycling centres. Some of these are resold while others are recycled. “We have been lucky to be part of the landscape in making used fashion part of the UK retail,” said Mr Bethell, who acknowledges that others have been part of this journey also. “People are locking themselves to the Houses of Parliament, super-gluing themselves to a Docklands Light Railway (DLR) train in Canary Wharf, they were not doing that seventeen years ago.” On the changing UK retail environment Bethell admires John Lewis “in such a tough climate they are working hard to make it right”. Specific to their work together: “I think what’s really fantastic is that the people at John Lewis have seen that we have been a key player in vintage and that we don’t just dump it, that we take it and make it into something”.

Global brands are recognising the value of creative partnerships. Bank and Vogue has worked with Urban Outfitters, Top Shop and most recently with the sneaker brand Converse on its Converse Renew Denim Collection. Wear and customisation have always been a feature of the denim story that appeals to the consumer. Classic vintage denim material in different shades is utilised in the uppers of Chuck 70 style. The approach maximises the unique in each shoe (not just each pair) that is married to the need for scalability in the manufacturing process needed for efficiency and to make it cost effective.

Bank and Vogue provides denim to the right weight, weave and colour so that one pair of jeans is used to create one pair of Converse Renew Denim Chuck 70. Affordability remains crucial, with scaleability a cornerstone in achieving this. Bank and Vogue are applying scaled manufacturing to a creative vision that makes its value proposition unique. Its appeal across continents, brands and consumers points to its success and the need that it fulfils within the circular economy.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more