Swiss machinery on display in Uzbekistan

Talking Heads is a new Innovationintextiles.com column, which features interviews with the industry’s movers and shakers. Adrian Wilson reports from the pre-ITMA Swissmem conference.

13th October 2015

Innovation in Textiles

|

Horgen

Talking Heads is a new Innovationintextiles.com column, which features interviews with the industry’s movers and shakers. Adrian Wilson reports from the pre-ITMA Swissmem conference.

CEOs of European manufacturing companies devote just 3% of their time to thinking about the long-term future of their organisations, according to a recent survey of German industrialists.

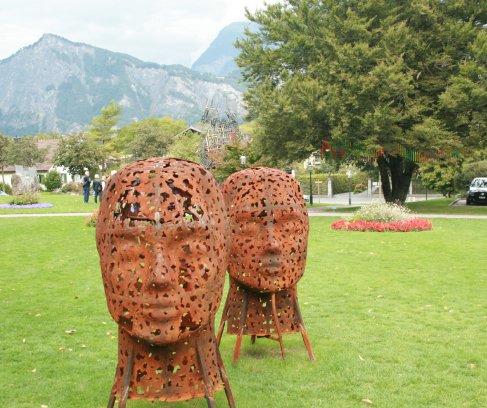

This observation, by Stephan-Friedrich von den Eichen, of IMP Consulting, kicked off a discussion held on September 20th in the spa and health resort of Bad Ragaz in Switzerland, which is currently holding the sixth Badragartz – the largest urban outdoor art exhibition in Europe.

The occasion was a pre-ITMA press conference held by Swissmem, to coincide with the Swiss textile machinery association’s 75th anniversary celebration weekend.

Responding were Ernesto Maurer, CEO of SSM and president of Swissmem and Martin Folini, CEO of Saurer.

SSM is a leading manufacturer of yarn processing and precision winding technology with 240 employees and annual sales of between €70-90 million.

Saurer, meanwhile, with 4,000 employees worldwide and annual sales of around €1 billion, draws on over 160 years of experience in improving production processes at different stages of the textile value chain, with a leading position in many areas of textile technology.

Von den Eichen went on to suggest that being too close to established customers and constantly attending to their needs was perceived as an industry strength, but would actually kill the European textile machinery industry in the longer term.

Stephan Friedrich von den Eichen: It’s a paradox, but it seems there is a constant pressure to meet immediate demands and no chance to step back and think further ahead. How can it be resolved?

Ernesto Maurer: It’s true that you are constantly measured by what you can do this year, in terms of profitability. To think about the future is a luxury, but maybe a necessary one. It’s hard though, not to get drowned in immediate operational issues.

Martin Folini: There’s probably some truth in it, and I can see the perceived danger. Not one of the big ski manufacturers saw snowboarding coming, for example, so there’s a danger in just concentrating on what you do already.

SVdE: What about niche markets?

EM: Going into the one dollar t-shirt market is certainly not the right place to be. We have obviously lost the markets for mass production in Europe and high-end technical textiles are where companies like us are very good. Not many Swissmem members are serving the market for mass production, and when they are, they are making the machines in India and China.

MF: Niches are not of interest to us. Our machines are involved in producing around thirty per cent of the world’s cotton-based clothing production. And together with Rieter, we probably share around sixty per cent. We have to be globalised, with a focus on Asia, where the markets continue to grow.

SVdE: It seems that as two companies – SSM and Saurer – you have completely different strategies and the two should not be compared?

EM: SSM is in some niche markets but I think there’s a lot of room for improvement.

SVdE: Perhaps you have not understood your core competences too well?

EM: We have a sound understanding of processes built up over decades but we are not involved in too many industries, it’s true. We are currently looking at what our textile technologies could do, for example, for the plastics industry. But speaking of a global approach, our next manufacturing plant – and it certainly isn’t planned for some time – will be in Europe. We are celebrating our 13th year in China and manufacturing there has been excellent, with fast response and a good cost structure. But those countries who didn’t go to China back then certainly shouldn’t go now. They should look to Cambodia or Vietnam, or maybe even Poland or Portugal.

SVdE: What about attracting young people to your industry in Switzerland, is this a problem?

MF: Google has an office in Zurich, as does Saurer. If you were a young and talented person, which one would you be most attracted to join? The problem is that the textile industry is perceived as being old and its technology dying out.

SVdE: So how can you change that?

MF: It’s a big problem for us. Saurer is a one hundred per cent export-orientated company, so if they live in Switzerland, chances are young people have never even heard of us.

EM: If I can get a young engineer into the company, the chances are, he or she will stay with us, but this is a luxury problem we have, really.

SVdE: But you need to bring in talent from outside Europe?

EM: Yes, but there’s a cultural issue too. There’s a difficulty in bringing in people not accustomed to European culture. In Europe you can challenge the boss, but parts of Asia it’s unheard of. This is a clear strength for Europe, when considering the future.

VdE: But isn’t being open tricky, overall? What about being open enough to co-invent with other companies? What about Swiss SMEs in particular, working together?

EM: Although Switzerland’s prosperity was built on textiles and engineering in the late half of the 19th and early 20th centuries, it took the crisis of World War 2 to bring the industry’s machinery manufacturers together in the first place. We are not in a crisis now. We are still complaining from a very high level, which is something us Swiss are very good at.

MF: No, we are not in a crisis.

EM: Back in 2009, then we really were in a crisis, when sixty to seventy per cent of our business vanished overnight.

MF: That was shocking, but it was worldwide. My feeling though, is that 2016 will be a difficult year. There are so many issues – fluctuating exchange rates, vastly varying oil prices, subsidies in China, and so on. Everybody is waiting to see what is going to happen. China is now trying to force a change in textile manufacturing from the east to the west of the country. Nobody is investing on the established east coast centres and it could become a problem in the next few years.

VdE: But it’s not such a big problem overall?

MF: No, it’s not.

VdE: So can I suggest the right time to make real breakthroughs is right now? When there is no real crisis, there’s the space to think about new structures and models.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more