Kelheim and Celliant at the Dornbirn-GFC

With a total of five lectures the medium-sized viscose speciality manufacturer puts itself in the same league as the industry’s big players.

2nd September 2015

Innovation in Textiles

|

Kelheim

Kelheim Fibres, the leading producer of viscose speciality fibres, seizes the opportunity to present the company’s latest findings of its in-house R&D at this industry gathering.

With a total of five lectures the medium-sized viscose speciality manufacturer puts itself in the same league as the industry’s big players – and the broad spectrum of topics is impressive, too, the company reports.

The Bavarians are engaged in the production of innovative materials consisting of bio-polymers and their tailored functionalisation.

Dr Philipp Wimmer will show how the combination of bio-polymers can create new composite materials in which the beneficial properties of all components can equally co-exist and can so enable new applications – as for example in the field of medical products.

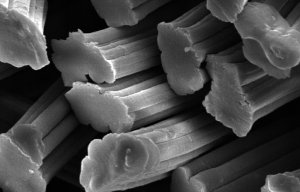

Viscose fibres can be used as a precursor for the production of carbon fibres. At the moment, the main area of application of viscose fibre-based carbon fibres is in high-temperature insulating materials.

Dr Roland Scholz will show how the carbonisation of viscose fibres of different shapes and sizes and with various functionalised additives incorporated in the fibres enables an amplification of possible structures and properties of carbon fibres and gives the potential for new fields of application.

Dr Ingo Bernt will talk about viscose fibres with inorganic contents, in particular about Kelheim’s flame retardant Danufil BF fibre. Here, a modified spinning dope is designed to ensure an extremely homogenous distribution of the silicanetwork – and therefore a fibre with very special flame retardant properties, without the necessity to use further FR-additives.

Nonwovens made from these alloy fibres do form very stable barrier layers and show a low smoke emission. The production of textile processable fibres with low denier opens further areas of applications, the company believes.

In textiles or nonwovens, a viscose fibre with incorporated IR-reflecting particles can help to reflect the thermal radiation, which is released from the human body. The wearer feels the advantage from this thermal retention function as well as from the viscose fibres’ typical properties (e.g. softness). Dr Daniela Bauer will explain how the intrinsic thermal effect works and which products can benefit from it.

And last but not least, Horst Wörner will present a high performance functional fibre, which has been developed by Kelheim Fibres and their long-standing partner Outlast Technologies. This is a filling fibre for insulation textiles, such as bedding articles or outdoor apparel, which – in a combination with other filling materials such as downs – is said to enable an active temperature management by the PCMs incorporated in the fibre.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more