Lightweighting progress from KraussMaffei

The new system uniquely combines the direct injection of the matrix material and the radius pultrusion process.

21st February 2017

Innovation in Textiles

|

Munich

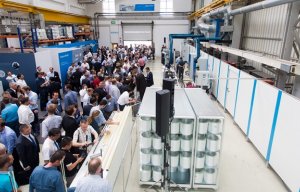

At the forthcoming JEC World show in Paris, Munich-headquartered KraussMaffei will introduce its new iPul pultrusion machine for highly-filled fibre-reinforced composite components.

At the forthcoming JEC World show in Paris, Munich-headquartered KraussMaffei will introduce its new iPul pultrusion machine for highly-filled fibre-reinforced composite components.

The new system uniquely combines the direct injection of the matrix material and the radius pultrusion process.

“The direct injection of the matrix material using a metering machine and an injection chamber offers clear technical and economic advantages compared with the typical market practice, where impregnation is generally effected by pulling the reinforcement through a bat,” says Josef Renkl, head of the company’s pultrusion development. “To date, pultrusion speeds are generally 0.5 to 1.5 metres a minute, but with the new iPul we are aiming for speeds of more than three metres a minute. This opens up completely new markets for pultrusion. In addition, the machine is able to manufacture not only straight but also curved profiles.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more