Report adresses adoption of composites in infrastructure

CreateMe founder Cam Myers outlines his company’s automation – built for how clothes should be made now.

22nd September 2025

Innovation in Textiles

|

Newark, California, USA

The sophisticated microelectronic laminates of the 2025 iPhone have been one inspiration for an entirely new approach to integrated garment manufacturing that is being taken by Newark, California-based CreateMe.

The company’s first 1,200-square-foot line incorporates a high-precision MeRA (modular-engineering robotic assembly) line powered by AI and machine learning techniques for sensing, manipulating and assembling deformable 3D materials at speed, with an output of an annual million fully finished garments.

Substantial IP

This has been developed following substantial research and development – to date, CreateMe has produced more than two hundred prototypes and conducted over a thousand process tests. Its technology is now covered by 95 patents, as part of a substantial IP portfolio.

The aim, says Cam Myers, who founded the company in 2019, has been to enable the realistic near shoring of apparel manufacturing based on a handful of such lines.

“I have a background in technology and software development and was involved in a previous e-commerce launch through which I became well aware of the problems the garment manufacturing chain faces in terms of stocking and inventory,” he explains. “In looking for potential options for near shoring I looked to Silicon Valley and the high velocity automated assembly of consumer electronics like the iPhone, which basically involves the lamination of microelectronics for which adhesives are a key.”

This insight – taking adhesives as the foundation for a new kind of garment assembly – has shaped a company intent not on incremental improvements but on transforming an entire industry.

Bottleneck

For over two centuries, apparel manufacturing has been dominated by sewing, but it remains the single largest bottleneck in the production chain.

“Sewing requires an incredible amount of dexterity and skill and that reliance on highly trained human labour creates bottlenecks,” Myers notes. “In the USA low-cost, high-volume sewing capacity is scarce and this has pushed much of the industry offshore.”

CreateMe’s alternative is to replace thread with advanced adhesives, applied through a system the company calls Pixel.

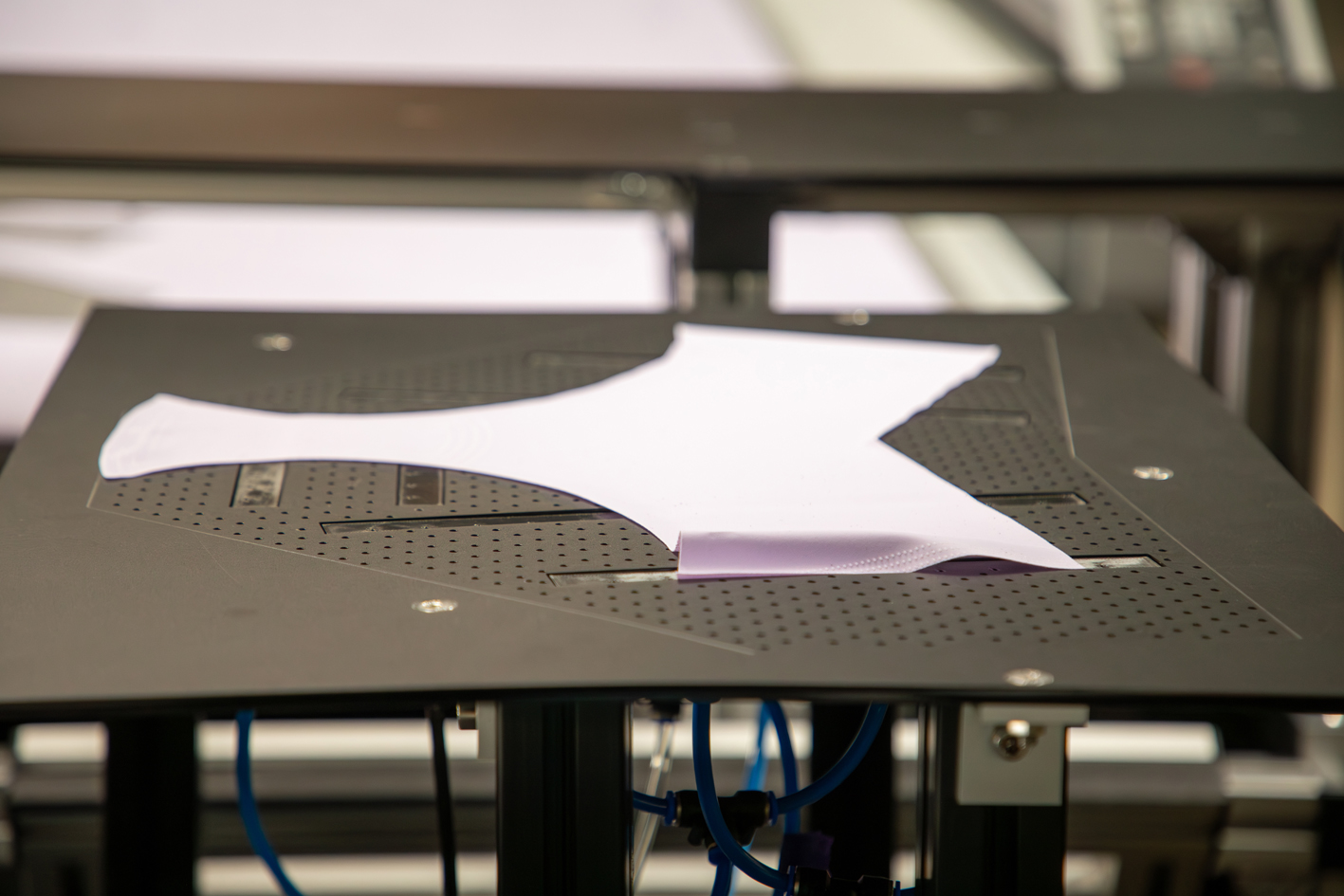

Pixel, and its companion brand PixelBond, exploit the use of micro-dot adhesive printing to bond fabrics together with extreme precision. Instead of bulky seams or thick seam tapes, Pixel lays down advanced bonding agents in fine, patterned points. This creates garments that feel soft and light, with their stretch and recovery properties preserved – qualities that are often compromised by thicker seam tapes. At the same time, adhesives are more compatible with robotics than needles and thread, enabling machines to assemble garments at speeds up to 20 times faster than manual sewing – and with twice the precision.

Machine vision

The Pixel system operates within CreateMe’s broader MeRA manufacturing architecture as the engine that enables the adhesives to be deployed at industrial scale, with sub-millimetre accuracy and real-time quality monitoring.

In CreateMe’s Newark facility, MeRA brings together more than fifty axes of robotic motion with 65-megapixel machine vision, orchestrating the delicate task of assembling soft textiles into finished garments.

Sustainability by design

While speed and efficiency are crucial, CreateMe has also designed its technology around sustainability.

The company’s Thermo(re)set platform embodies this principle. Thermo(re)set refers to a range of thermo-reversible adhesives that can be undone with heat. Instead of locking fabrics together permanently, these bonds can be released, allowing garments to be taken apart at the end of their life. Fabrics can then be separated, sorted, and recycled into new textiles.

“Our adhesives can be de-laminated using heat, making it much easier for them to be separated, sorted and recycled at scale.” Myers explains. “Unlike conventional approaches, which treat sustainability as an add-on to existing processes, we are embedding circularity directly into the design of the garment, with no limitation on size, shape or sillouhette. This chimes with wider trends in policy and regulation.

“The timing could not be better with the Extended Producer Responsibility legislation currently being enacted in Europe and in certain US states that bring enhanced requirements for end of life management of apparel products. This is a game changer for enabling the wider adoption of locally produced apparel and to facilitate recycling.”

Real time response

The business case for CreateMe is as compelling as the technical one.

On a single production cell that can produce more than one million garments per year, lead times of just 48-72 hours are possible, enabling apparel brands to react to consumer demand almost in real time. Inventory can also be constantly turned as opposed to traditional offshore models, to accelerate cash flow, reduce waste and cut down on overproduction, which has long plagued the fashion industry.

By enabling production to take place close to consumer markets, CreateMe’s model also reduces the need for long-distance shipping and the associated carbon emissions. The company estimates its system can significantly cut apparel’s carbon footprint compared with airfreight. For brands under pressure to demonstrate both profitability and sustainability, these efficiencies are difficult to ignore.

Brand options

The company is currently in discussions at various stages of progress with 15 major brands and manufacturers.

“Some may opt to license the technology, others may form joint ventures, and still others aim to rely on us directly for advanced manufacturing services,” says Myers. “In each case, the promise is the same – garments that are assembled without sewing, manufactured with speed and accuracy, and designed to be recycled. The first intimates product range based on CreateMe production will be commercially launched in the fourth quarter of 2025.

“This is a strategic entry point, since lingerie and undergarments demand both precision and comfort – qualities that showcase the strength of our adhesives and the accuracy of our technology. From there, we plan to expand into t-shirts in the first quarter of 2026, followed by moves into athleisure, sportswear, and eventually into all areas of casual apparel.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more