Santoni introduces denim evolution

Building an engaged and connected community for the future of European smart textiles and establishing the industrial value chains that are needed.

25th April 2022

Innovation in Textiles

|

Brussels, Belgium

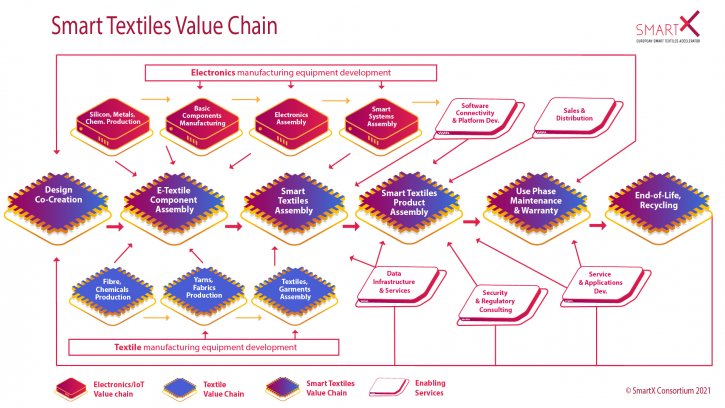

SmartX Europe, the European Smart Textiles Accelerator, has launched a new manufacturing value chain map for the rapidly growing smart textiles industry.

The three-year acceleration platform for smart textile projects has been driven by a cluster of thirteen European partners from the textile and technology industries and is providing support to 25 individual projects with a total budget of €2.4 million.

Its primary objective was to build an engaged and connected community for the future of European smart textiles and to shape and establish the industrial value chains that are needed.

The smart textiles value chain comprises multiple actors from three distinctive industries – electronics, textiles and ICT (information and communications technology). As a result there is a need for cross-sectoral partnerships because it is challenging to bring together competencies, energies and strategies based on three very different industries, viewpoints and mindsets.

The analytical map aims to provide a clear vision of the whole interactive pattern and to identify the current gaps that slow down or jeopardise the successful development of the European smart textiles industry.

Current challenges

There is no clear absence of any specific element, but rather a weakness in many of them that comes from little collaborative history between the three industries concerned, the SmartX consortiun says. Furthermore, the still insufficient development of volume markets prevents most of the large businesses that predominantly supply equipment machinery, chemical and electronics components from dedicating much effort and investment to smart textiles production.

Technological breakthroughs are not what is primarily missing in order to allow the industry to shine in the global market. Ideas are there, researchers and patents as well, but the movement is led by start-ups and SMEs who have to cope with small series production and high costs. They serve a few lead customers in specific market niches, have to work with adapted equipment and very limited automation and modified chemical formulations, and need to add required new skills in the workforce.

Promising trends

There are however promising technological trends, such as the current development of low power flexible and organic electronics, as well as the more automated integration of conductive elements into conventional textiles through knitting, embroidery or printing, which will help to achieve lower cost levels and more reliable quality, as well as better functional properties.

To meet the existing challenges, several highly promising fields are opening up to the industry. The most important one is the development of flexible electronics, which allow for efficient connections between soft material substrates and hard metal components and the use of hybrid chip platforms – systems-on-chip with a low-power coprocessors – which translate into significantly better performances and user experience.

One major drawback the industry has to face is the insufficient integration of marketing in the broad sense, by developing unique selling propositions, identifying how and why the smart textile product is better than existing solutions. These are concerns to which smart textile businesses often give too little attention too late in the product development process.

Another key issue to solve as soon as possible is the lack of widespread and clear regulations and norms, be it in the design of products, services, or data management. International norms and trade rules are needed to ensure both user safety and a level playing field for industries worldwide.

Any smart textile development project must actively involve all relevant stakeholders going forward, the consortium concludes.

This includes designers, manufacturers, end users and experts on end-of-life treatment, as well as experts on service and application development. Building a successful community – one of the goals accomplished by the SmartX programme – has been of crucial importance to ensure all talents, capacities and knowledge work in better synergy throughout the industry.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more