Largest-ever order for Oerlikon Neumag

Oerlikon Neumag reports that it has successfully commissioned three staple fibre bicomponent systems in China

28th August 2020

Innovation in Textiles

|

Neumünster

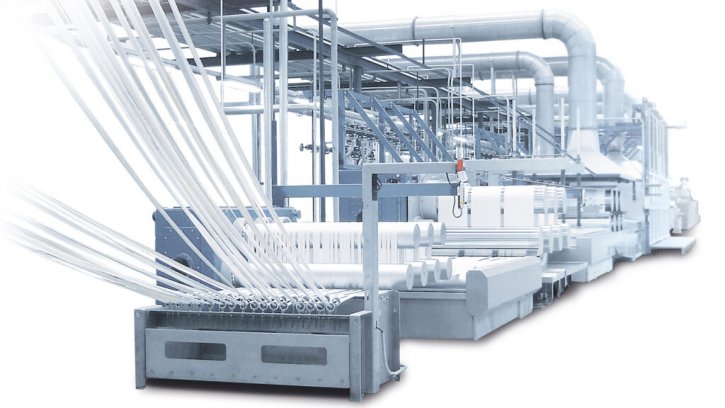

Oerlikon Neumag staple fibre plants stand for highest product quality and absolute reliability. © Oerlikon Neumag.

Oerlikon Neumag reports that it has successfully commissioned three staple fibre bicomponent systems in China. With capacities of 50 tons per day each, the systems are being used to manufacture coresheath bicomponent fibres made from PP/PE or PET/PE at two long-standing Oerlikon Manmade Fibers customers. The fibres are used to make hygiene products.

Despite coronavirus-related restrictions, the three new systems were installed within three and five months, all without any problems, the company says. They have meanwhile been operating under stable production conditions with optimum fibre quality of the very highest standards for several weeks now, it adds.

Experience in bi-component spinning

Oerlikon Neumag looks back on many years of experience in constructing bicomponent staple fibre systems. The first system for this fibre type was commissioned as far back as 1995. Oerlikon Neumag offers solutions for the most varied cross-sections, ranging from sheath/core’, ‘side-by-side’, ‘island in the sea’, ‘orange type’ as well as ‘trilobal’. The applications are diverse, from self-crimping fibres, bonding fibres, super-microfibers all the way through to hollow fibres, Oerlikon Neumag explains.

“The Oerlikon Neumag bicomponent technology is particularly characterized by the extremely robust spin packs that have no expensive wear parts, which considerably reduces the costs here. The reconditioning costs when cleaning the spin packs are kept to an absolute minimum. Add to this the separate temperature transfer option in the spinning beam for the two polymers. As a result, the quality and the viscosity of the polymers can be accurately adjusted in accordance with the respective process requirements,” the company concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more