Andritz at INDEX23

Eliminating the so-called ‘smile’ effect in nonwovens production.

30th April 2021

Innovation in Textiles

|

Graz, Austria

Maximising the evenness of nonwoven fabrics across the entire line they are being manufactured on is one of the keys to competitive and sustainable products.

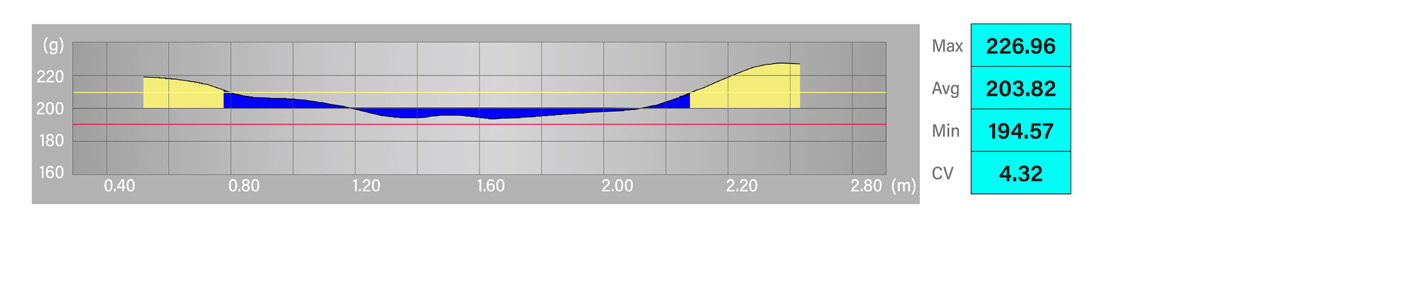

As nonwoven webs are laid and processed, the fibres have a tendency to move to the edges of transportation belts and individual machines, leading to the so-called ‘smile’ effect and a lack of homogeneity in the web if not constantly corrected.

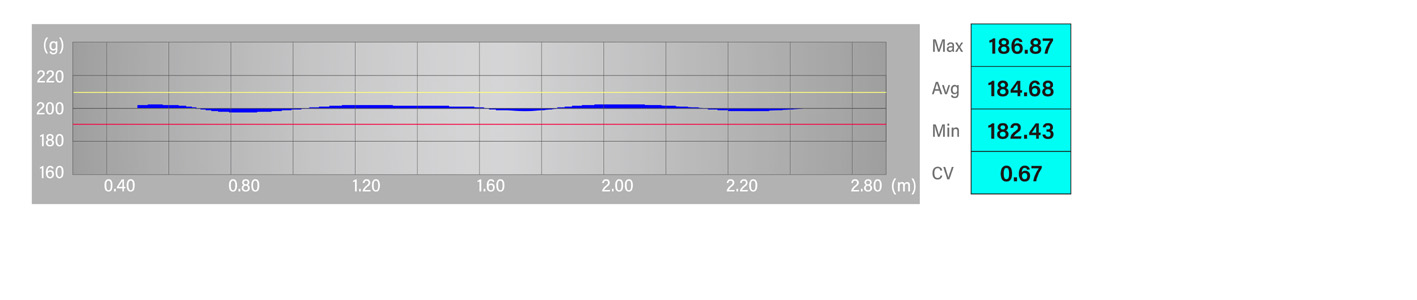

ProWin is the latest development from Andritz for ensuring web evenness, allowing nonwoven producers to achieve optimum weight profiling at the crosslapper delivery and also increase their running process speeds by up to 15%. The new unit complements the company’s existing ProDyn and ProWid profiling units.

“We have developed a self-regulating, advanced technology to reduce fibre deposits at the edges of the web and eliminate the ‘smile’ effect across its width,” said Guillaume Julien, head of needlepunch sales at Andritz Nonwoven. “ProWin enables producers to optimize the coefficient of variant – CV – ratio autonomously and precisely while also generating significant fibre savings of up to 10% and increasing production speed. As such, it provides a fast return on investment.”

In the spunlacing process, a better product quality can be obtained by ensuring that the different equipment units in the production line are consistent with one another. The Andritz TT card, Jetlace hydroentanglement unit and neXdry through-air dryer combine to obtain premium visual quality and characteristics in the web. For an equivalent amount of fibres, this set-up is designed to produce an even web with significant bulkiness and an excellent MD:CD ratio, without impacting the production capacity.

The wasted edges of the spunlace fabric retrieved as a result of profiling can be successfully reintroduced into production without any change in quality.

Anditz also offers a range of service apps for maximising production. The Metris Cost Management app is used to track raw material consumption, allowing in-depth diagnosis of raw material losses and savings achieved in the different process areas of a line.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more