Groz-Beckert presents latest in felting and carding

Groz-Beckert has expanded its application consulting services with the staple fibre needle punch line.

31st July 2018

Innovation in Textiles

|

Albstadt/Shanghai

Groz-Beckert, a leading provider of industrial machine needles, will be represented at Cinte Techtextil China, Asia’s leading biennial trade fair for technical textile and nonwoven products, which takes place in Shanghai, in September, with its extensive product portfolio and range of services in the fields of felting and carding.

The felting product area will be presenting its products and services at the trade fair. As a development partner, Groz-Beckert has expanded its application consulting services with the staple fibre needle punch line. The line is available in various versions to customers and partners for tests and joint projects in both needle and textile development. At the Groz-Beckert booth, visitors will have the opportunity to experience the technology line live. “The 3D print model in scale 1:18 of the original line in the Textile and Development Center (TEZ) at the Groz-Beckert headquarters in Albstadt, Germany, impresses with its wealth of technical detail,” the company reports.

Groz-Beckert will also be focusing on special needle solutions for good surface quality in pre-needling. The Gebecon felting needle offers improved stability compared with a conventional standard felting needle – combined with good needle flexibility. Groz-Beckert will be highlighting this and other advantages in a live demonstration on a miniature needling machine and a man-high needle model.

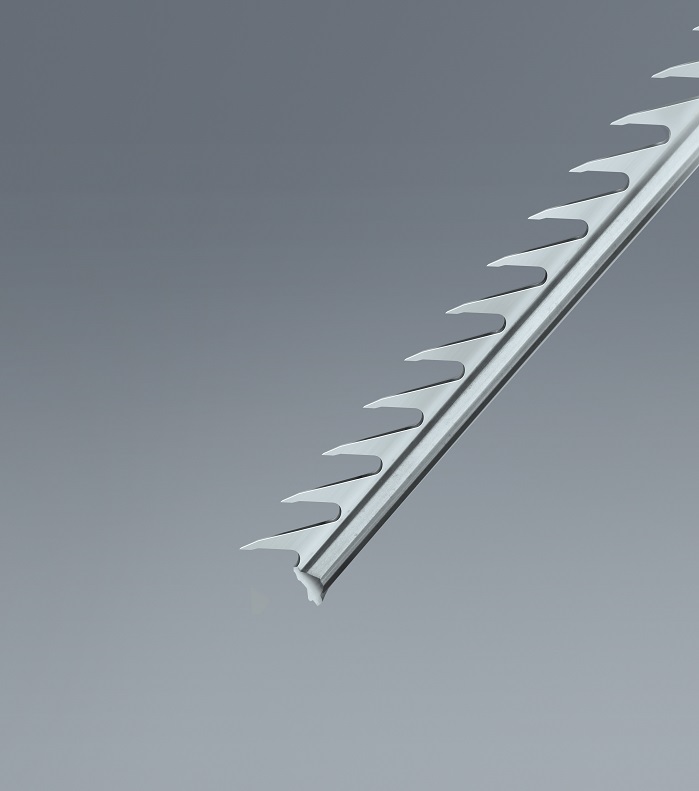

In addition to the EcoStar felting needle and the new Groz-Beckert dur needle, the company will also be presenting the HyTec P jet strip – its latest product for hydroentanglement. As well as improved handling properties, the innovative jet strips also feature significantly higher hardness, which is said to have a positive effect on all mechanical properties such as scratch resistance, bending strength and service life.

The Carding division will be presenting its extensive product range for the nonwovens industry at the exhibition. This includes optimal specifications for a wide range of applications. A selection of card clothing will be available to view at the Groz-Beckert booth on a roller top card model made from acrylic.

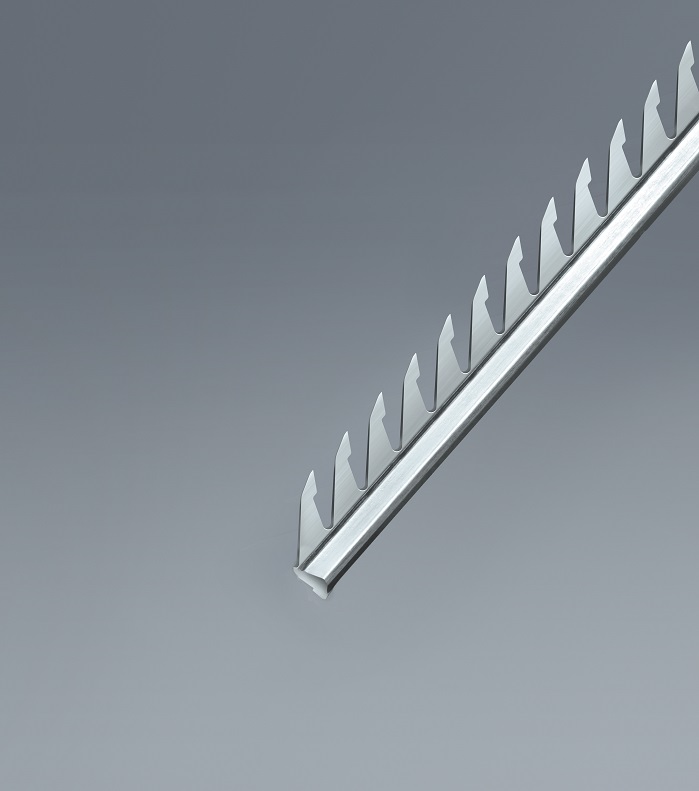

The focus here will be on increasing performance and saving raw materials: Thanks to the improved fibre control, the EvoStep high-performance worker and doffer wire distributes the fibres more uniformly in the web and helps to achieve the nonwoven properties more efficiently. This means that the use of raw materials can be reduced to a minimum, the manufacturer explains.

The SiroLock high-performance worker and doffer wire also offers opportunities to save on raw material – mainly through the more uniform web quality. It also offers increased performance thanks to the higher achievable delivery speeds and web weights. Alongside the increased performance without fibre fly, SiroLock also offers improved blending of the fibres.

Groz-Beckert is a leading provider of industrial machine needles, precision parts and fine tools as well as systems and services for the production and joining of textile fabrics. The products and services support the fields of knitting, weaving, felting, tufting, carding and sewing. The family-owned company, founded in 1852, operates with agencies, production and distribution subsidiaries in more than 150 countries around the world.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more