Karl Mayer partners with leading denim brands

Hollow fibre membranes are used in filtration systems where the stakes can be unusually high – even between life and death.

7th November 2025

Innovation in Textiles

|

Singapore

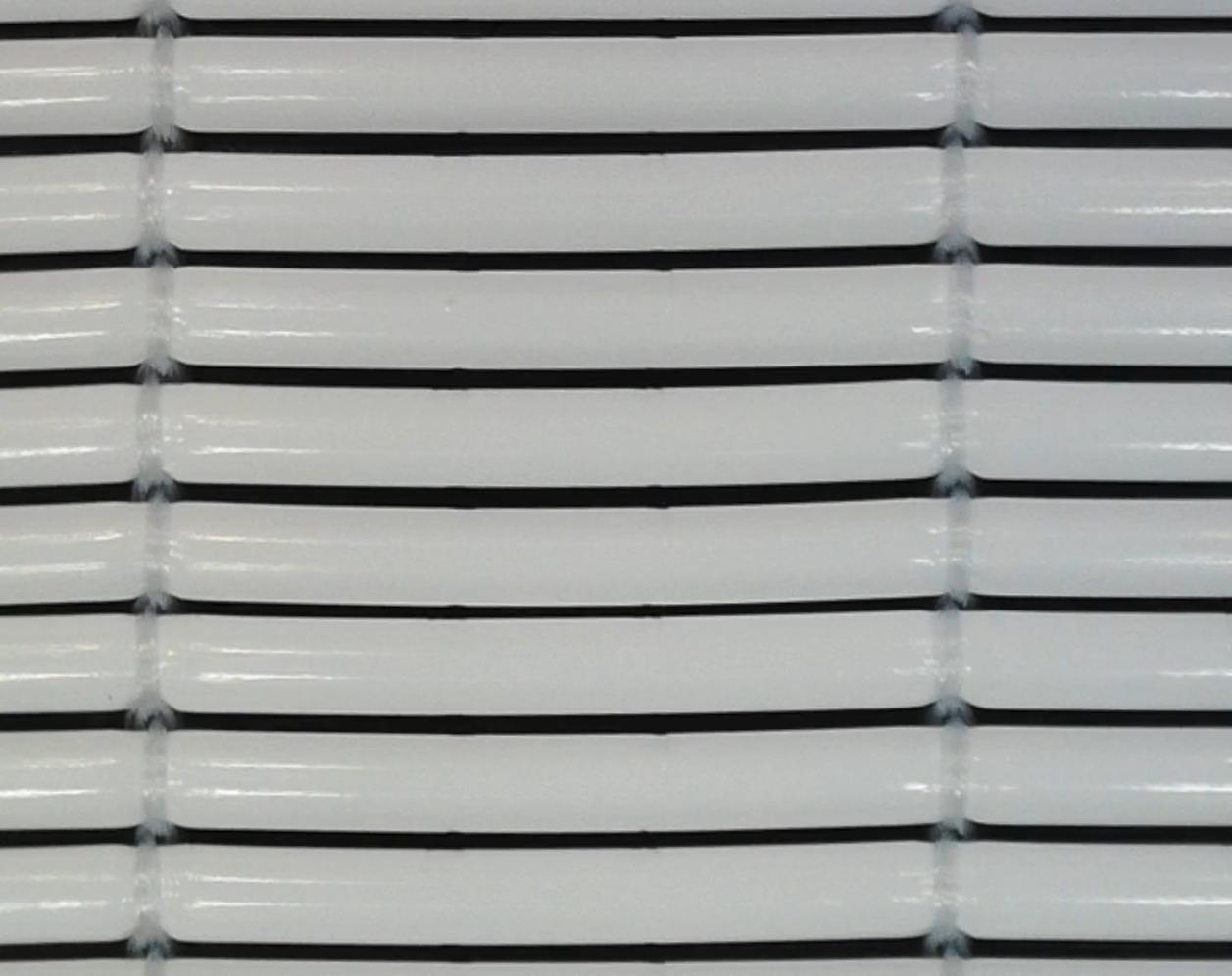

Hollow fibre membranes are among the most refined structures used in modern filtration and their production relies on the precise handling of extremely small and structurally sensitive fibres that is enabled by Karl Mayer’s Wefttronic RSP Weft knitting technology.

Delicate structures

With outer diameters typically up to 0.5 millimetres and wall thicknesses as fine as 20 microns, each individual fibre has a round, open lumen running through its centre.

The preservation of this delicate fibre structure during processing is crucial to the function of the membrane.

If a fibre is squeezed – even slightly – the lumen can collapse and if abraded in any way, tiny perforations can form. If it is bent sharply, the internal structure can fatigue and fracture.

The difficulty in producing membrane sheets, therefore, is not simply to place fibres into a regular textile structure, but to do so without imposing the sort of forces that ordinary knitting machinery exert as a matter of course.

Gentle guiding

Karl Mayer’s Wefttronic RSP Weft system has been engineered from the outset around the particular behaviour of hollow fibres.

Rather than forcing the fibre into the knitting area, the geometry of the machine guides it. The fibre approaches the needles at a shallow angle and leaves in a direction that continues the flow, so that the resultant force acting on the fibre during stitch formation is extremely low.

The machine, in effect, is arranging the fibres rather than gripping or pressing them. The needles selected are much finer than those used in standard warp knitting, which prevents the walls of the fibre from being distorted, while the sinkers are spaced so they do not trap the fibre between hard surfaces. The fibre is always supported, but never compressed.

This principle extends along the entire yarn path. From the creel to the knitting zone, the fibres are fed in straight, gently guided lines over smooth-running rollers at minimal deflection angles. The creel itself is not passive, but actively driven and synchronised with the machine so that the fibres are supplied under steady, low tension rather than being dragged from stationary packages.

The fibres are therefore kept aligned and stable, with just enough tension to prevent slackness, but never so much that the lumen is stretched or strained.

Once the textile structure has formed, the take-up and later handling stages continue the same logic. The fabric is guided without pressure, cut with heat so the edges seal cleanly, and wound with low and controlled tension to preserve the fibre profile.

Separate and supported

Rather than tight mechanical binding, the fibres are positioned in an ordered arrangement, held in place by the way the loops interlock rather than by force.

This regular spacing is precisely what the subsequent membrane module requires.

When thousands of fibres are later assembled into filtration packs or gas-transfer modules, their performance depends on each fibre behaving identically. If the fibres had been squeezed, misaligned or deformed earlier in the process, the final module would not function reliably.

The textile structure formed on the Wefttronic RSP Weft ensures that each fibre remains separate, supported and positioned without stress.

High stakes

Hollow fibre membranes are used in systems where the stakes can be unusually high.

In medical life-support, for example, hollow fibre membrane oxygenators perform the gas exchange function of the lungs outside the human body. During extracorporeal membrane oxygenation, oxygen passes into the bloodstream through the fibre walls cleanly and consistently while carbon dioxide diffuses out, sustaining life when the lungs cannot.

In haemodialysis, millions of people worldwide rely on dialysers that use hollow fibre membranes to extract toxins from the blood while maintaining circulatory balance.

In both cases, the integrity of the fibre structure is critical. A fibre that is squeezed, flattened, abraded or micro-fractured cannot perform reliably, and the consequences could be severe.

Silent management

A comparable sensitivity – although less life threatening – applies in industrial settings. Breweries use hollow fibre membrane contactors to remove oxygen that could dull flavour, or to introduce nitrogen that gives beer its smooth, cascading head.

Semiconductor manufacturers meanwhile rely on dissolved gas control – measured in parts per billion – to avoid microscopic corrosion or contamination.

Power plants, chemical processing, printing inks and fine coatings all depend on the silent management of dissolved gases and in every case, the stability of the membrane depends on the immaculate preservation of each fibre’s geometry.

Recognition

Karl Mayer’s development of the Wefttronic RSP Weft represents a recognition that the value of hollow fibre membranes lies in their untouched precision, and that the textile framework around them must exist to preserve rather than reshape them.

By enabling these fibres to be handled gently, consistently and at industrial scale, the machine provides the foundation upon which dependable membrane modules can be built. It ensures that the performance designed into each fibre is carried intact into the final application – whether sustaining human life or maintaining the purity of critical industrial processes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more