Texprocess: Leading international trade fair for processing textile and flexible materials

In a total of four micro-factories at the up-coming Texprocess, trade visitors will be able to get an idea of how integrated textile processing works.

22nd January 2019

Innovation in Textiles

|

Frankfurt

Individualisation, automation and digitalisation: micro-factories are the way forward for the future of clothing production and will be the main theme of Texprocess, which takes place in Frankfurt, from 14-17 May 2019. In a total of four micro-factories at the up-coming Texprocess, trade visitors will be able to get an idea of how integrated textile processing works and where micro-factories are already being used.

“Send your favourite design to the manufacturer today via an app and wear your individually designed, perfectly fitting trainers or shirt tomorrow. It’s a long time since this was just a pipe dream for the future,” said Michael Jänecke, Director Brand Management Technical Textiles and Textile Processing at Messe Frankfurt. “Behind it, however, lies a host of complex processes, involving production, processing and logistics. Micro-factories, based on networked and integrated procedures, represent the progressive way of making textile processing quicker, more flexible and, because it is more local, also more sustainable; whilst, at the same time, producing personalised products.”

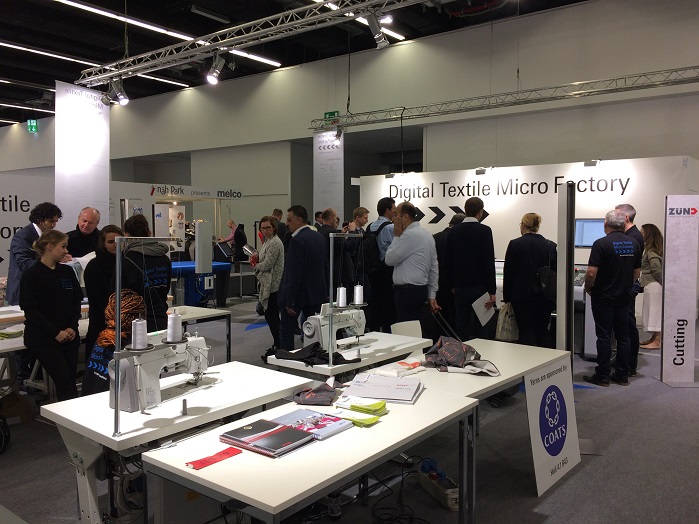

Following the success of the last event, Texprocess, in collaboration with the German Institutes of Textile and Fibre Research in Denkendorf and partners from industry, will once again be presenting a Digital Textile Micro-Factory display – and thus fully networked production chains – live in Hall 4.1. New this year: the Digital Textile Micro-Factory will showcase three production lines – one for apparel manufacture, one for 3D-knitted shoes and one for processing technical textiles, largely for the motor-vehicle and furniture industries.

The fashion industry plays a central role in the Digital Textile Micro-Factory. The customer’s digital doppelganger is becoming more and more important in development departments in the apparel industry, as the starting point for individualised and perfectly fitting clothes and for links with finishing departments. In the context of the micro-factory’s production line, it is the key feature.

The production line demonstrates the various stages involved, including CAD/Design, printing, cutting out, assembly, finishing and labelling. New approaches also combine 3D simulations of clothing with direct data transfer in virtual reality (VR) and augmented reality (AR). Instead of presenting the customer with physical examples of the clothing to be produced, the examples are visualised as virtual objects. And during the production process, the customer has the opportunity for direct input into the design of the product in question.

This direct interaction between the 3D simulation of an item, the representation in VR/AR displayed on the customer’s own hardware and the direct impact on the production process has never been shown before in this way. Partners of the Fashion Line are: Assyst (CAD/design), Mitwill (materials), Caddon, ErgoSoft, Mimaki and Multiplot (printing), Zünd (cutting), Juki and Stoll (assembling), Veit (finishing) and Vuframe (AR/VR).

Industry 4.0 live: the focus of the third production line of the Digital Textile Micro-Factory 2019 is on the automated processing of technical textiles, personalised for the individual customer, taking us right through to the finished product. Trade visitors will see here on-demand inkjet printing and networked machines with integrated sensors, which are linked through a bus system – a future-oriented topic for integrated manufacturing. A robot arm with a special claw for use with textiles sorts the cut items as they emerge from the cutter in a free-moving open shuttle. The items to be sewn are conveyed automatically to the sewing stations. Tracing and tracking procedures show the progress of each order through the individual stages of the manufacturing process using an auto ID.

In their Smart Textiles Micro-Factory, the Institute for Textile Technology (ITA) at the RWTH Aachen University, together with partners, will be producing a smart pillow, which, with the help of integrated LEDs, provides new ways of interaction. With this demonstration, the partners in the project will present an exemplary, industrial-style manufacturing process for a smart textile from design to finished product.

Six companies have grouped together under the World of Digital Fashion umbrella. They work in areas of visualisation, CAD-cutting systems, automated body measurement, cutting out and process automation. Together, they will be showcasing ways of integrating and combining their products in a variety of workflows within the value creation chain and will enable visitors to experience what the digital process chain is like in practice. The focus will fall particularly on the customisation of apparel and fashion items.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more