World’s first C2C Platinum for Rajby Textiles

Innovations were detailed in a major presentation on trends for the Spring/Summer 2021 season by Manon Mangin of the Première Vision Fashion Team

13th December 2019

Innovation in Textiles

|

London

Manon Mangin of the Première Vision Fashion Team outlines the trends for the Spring/Summer 2021 season at the London show.

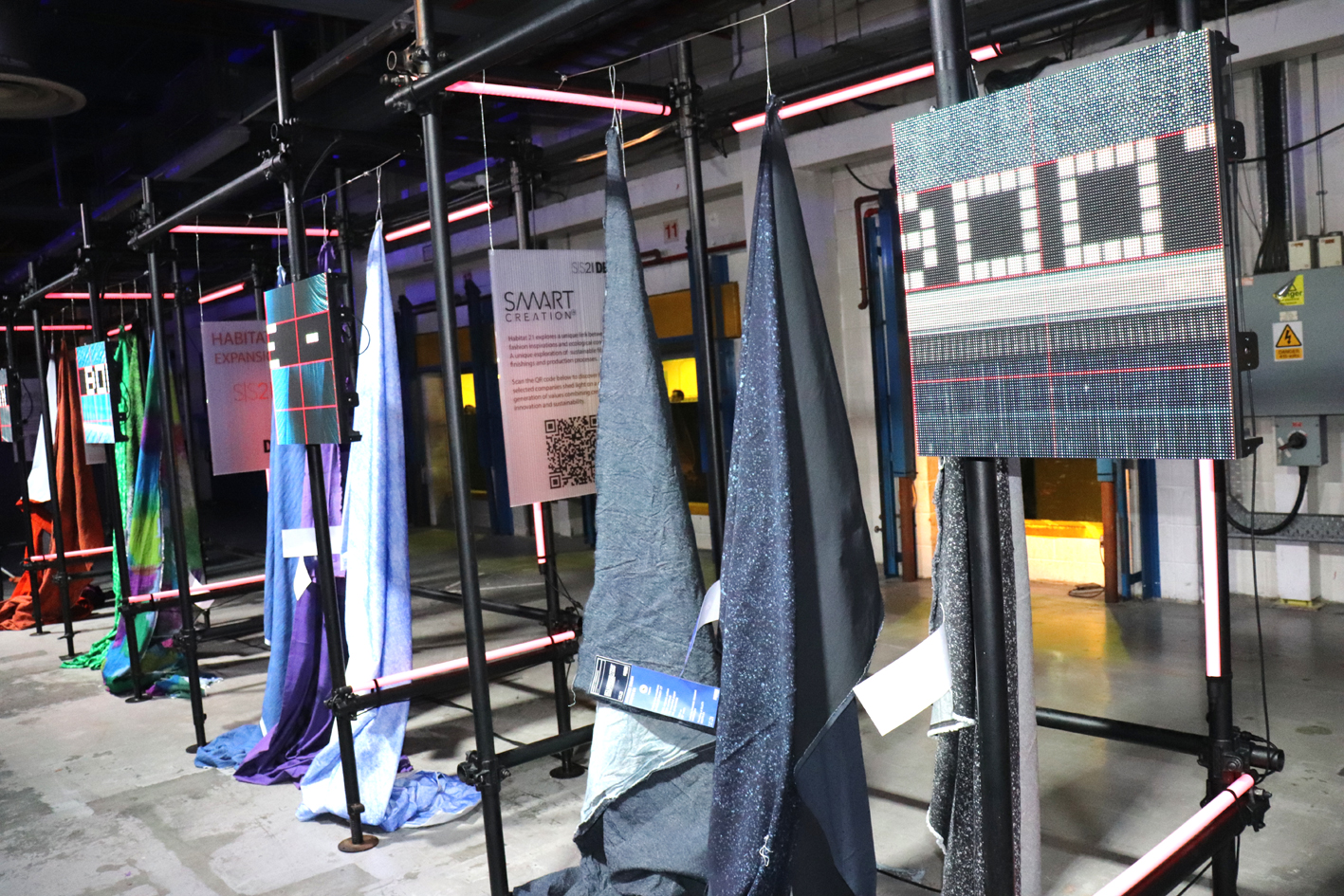

Of the twelve participating denim mills who took part in Habitat 21 – a special Smart Creation showcase at the recent Denim Première Vision exhibition in London – no less than eleven were valued Monforts ‘Denimized’ finishing technology users.

The aim of Habitat 21 was to highlight those companies taking an eco-responsible approach to denim manufacturing via the use of recycled, organic and bio-based fibres, in combination with resource-saving dyeing and finishing technologies.

Monforts customers involved in the project were Advance Denim, Berto, Bossa, Calik, Evlox/Tavex, Kilim, Naveena, Orta Anadalou, Rajby Industries, Raymond Uco and Soorty.

Their innovations were detailed in a major presentation on trends for the Spring/Summer 2021 season by Manon Mangin of the Première Vision Fashion Team, based on three key themes – Sensation, Hybridisation and Expansion.

Water savings

There was plenty of sustainable innovation on show from Turkey, with Bossa, for example, unveiling the latest creations from its ongoing Reset programme – first introduced in 2006 and constantly evolving its eco-friendly options – and Calik exhibiting a denim collection made with its D-clear process, via which water is reduced by 40% in indigo dyeing and by 83% in the subsequent finishing.

Habitat 21 – the special Smart Creation showcase at Denim PV.

Kilim is meanwhile intending to reduce water by 93% as a result of its current Cactus project, which will have a significant impact on the footprint of the 12 million metres of denim it makes annually, and in addition to resource-saving processes, Orta Anadalou is committing to complete traceability, with each of its garments now labelled with a unique QR code.

Hemp

Among innovations from Pakistan’s leading mills, Naveena made a splash with the introduction of its ‘cottonised’ hemp denim, developed in a collaboration with Kingdom Holdings – one of the largest manufacturers of hemp in China – in order to reduce the company’s reliance on cotton.

There are many challenges involved in working with hemp, Naveena says, but vertically-integrated spinning operations have enabled it to create blended yarns of cotton, hemp and Tencel containing only 49% cotton.

A complete Monforts ‘Denimized’ finishing range.

Both Rajby Industries and Soorty have now achieved Cradle to Cradle Gold certification for denim fabrics in their collections, as a globally recognised measure of safer, more sustainable products made for the circular economy.

To receive this certification, products are assessed for environmental and social performance across five critical sustainability categories – material health, material reuse, renewable energy and carbon management, water stewardship, and social fairness. The standard encourages continuous improvement over time by awarding certification on the basis of ascending levels of achievement and requiring certification renewal every two years.

Aniline free

Advance Denim has meanwhile become the first denim mill in China to launch a collection made with aniline-free indigo.

As a result of its toxicity, analine is now starting to feature on the restricted substance lists (RSL) of some of the major clothing brands and retailers.

During traditional indigo dyeing process, some aniline stays locked into the indigo pigment and is difficult to wash off the fabric, while the remainder is discharged with the wastewater. The new process being employed by Advance Denim is based on an aniline-free indigo formulation from Switzerland’s Archroma.

During traditional indigo dyeing process, some aniline stays locked into the indigo pigment and is difficult to wash off the fabric, while the remainder is discharged with the wastewater. The new process being employed by Advance Denim is based on an aniline-free indigo formulation from Switzerland’s Archroma.

Italy’s Berto also introduced pre-reduced indigo dyeing in an expanded range of denims based on GOTS-certified fabrics made with organic cotton and regenerated yarns.

“Our latest collection was inspired by young people – the Z Generation that is free spirited but at the same time involved in the fight against climate change,” said Berto’s marketing manager Francesco Polato. “We are seeking to meet their needs with an extroverted collection characterised by special colours and looks, but always with a 360-degree attention to sustainability.”

To complete the Smart Creation showcase, India’s Raymond Uco introduced a coloured denim range comprising fabrics that are both yarn dyed and made from sustainable dyestuffs, to significantly reduce the use of chemicals, while Evlox/Tavex announced plans to introduce post-consumer recycled denim to its collections, with complete traceability of all the materials used.

Denim Première Vision took place at the Printworks in London on December 2nd and 3rd. The next edition will be held in Milan in June 2020.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more